At one point in the book The Machine that Changed the World (Womack, Jones, and Roos, 1990), the authors compare the way cars are sold in the United States versus Japan. In the U.S., automakers manufacture thousands of cars and then ship them to dealerships around the country, where they sit on huge lots until they are sold. If a customer buys “off the lot,” he or she can drive away in a new car that same day. If, however, the customer wants to order a car with a particular combination of features, the process can take several months.

In Japan, by contrast, cars are sold door-to-door. A salesperson visits prospective customers in their homes and shows them the various offerings. Customers then place an order, specifying the color, trim, and options they want. Back at the office, the salesperson enters the order and the customer receives the car in approximately two weeks.

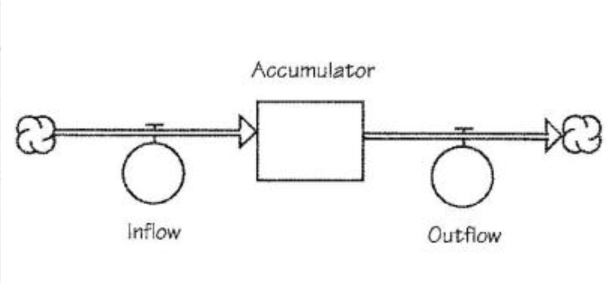

A Structural View of a Delay

However, Toyota’s management was not satisfied with the two-week delivery time. They knew their manufacturing cycle had a standard two-day turnaround time, so they commissioned a team to investigate the source of the additional delay. What they discovered was that it did indeed take only two days to manufacture the car. The remaining 12 days were spent on administrative tasks associated with processing the order!

“Invisible” Delays

The above story illustrates one of the tricky things about trying to manage a complex system — some delays can be less visible than others. Toyota spent years systematically identifying and eliminating the delays in its production process (such as buffer stocks of inventory). But delays in the office environment were much more difficult to recognize. This is because administrative processes are usually not tightly coupled, and they do not manifest themselves in the form of excess “stuff” piling up somewhere. When Toyota uncovered the administrative delay in its ordering process, it redesigned the system so that the orders could be put directly into the manufacturing system, thus reducing the processing delay.

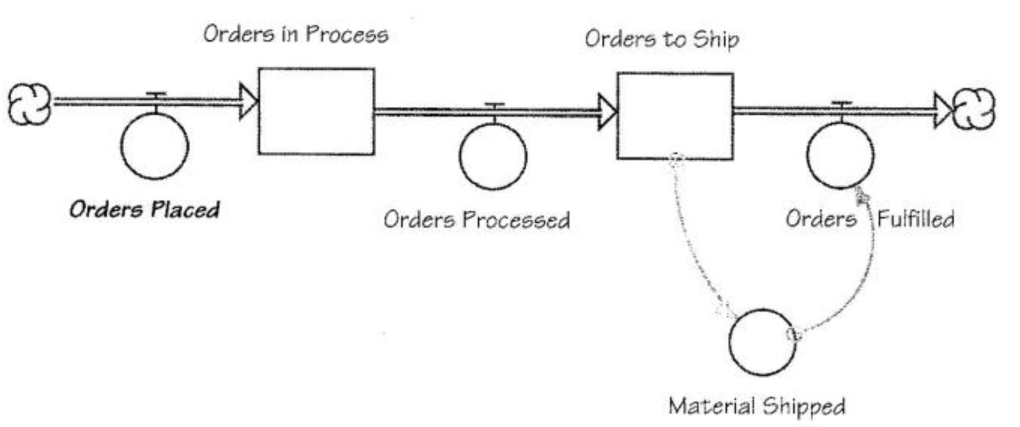

Order-Processing System

From a systems thinking perspective, the structures that produce delays look the same in any type of system and therefore can be made visible. They are represented by accumulators (or stocks), which highlight where any kind of “stuff ” accumulates in the system, whether it be car engines or office memos (see “A Structural View of a Delay”). The key, then, to discovering significant delays is to identify important accumulators in the system.

Managing Accumulators

A semiconductor manufacturer, for example, was concerned about a sudden increase in the number of customer complaints about delivery time — especially since it had recently implemented a more streamlined customer order system that appeared to be operating smoothly.

In this new system, orders were received at the company and processed within 48 hours of receipt. The approved orders were then sent off to the manufacturing department for shipment (see “Order-Processing System”). All departments were operating within the specified time parameters, and there was plenty of inventory on hand to fill orders without creating a backlog. So why were customers complaining about lengthening delivery times? The company’s managers suspected that there might be an “invisible” delay at work.

To uncover hidden delays, we need to take a closer look at the system and make sure that all the relevant flows are being tracked. In this case, the customer order system was evaluated by how quickly paperwork was processed for each order that came into the system. As orders came in, they were checked for completeness and entered into the system. Orders that contained incomplete or incorrect information were followed up on, while completed orders were entered and forwarded to the “Orders to Ship” accumulator, which alerted the factory to ship the merchandise. Since the factory had also been streamlined, inventory was always available for shipment.

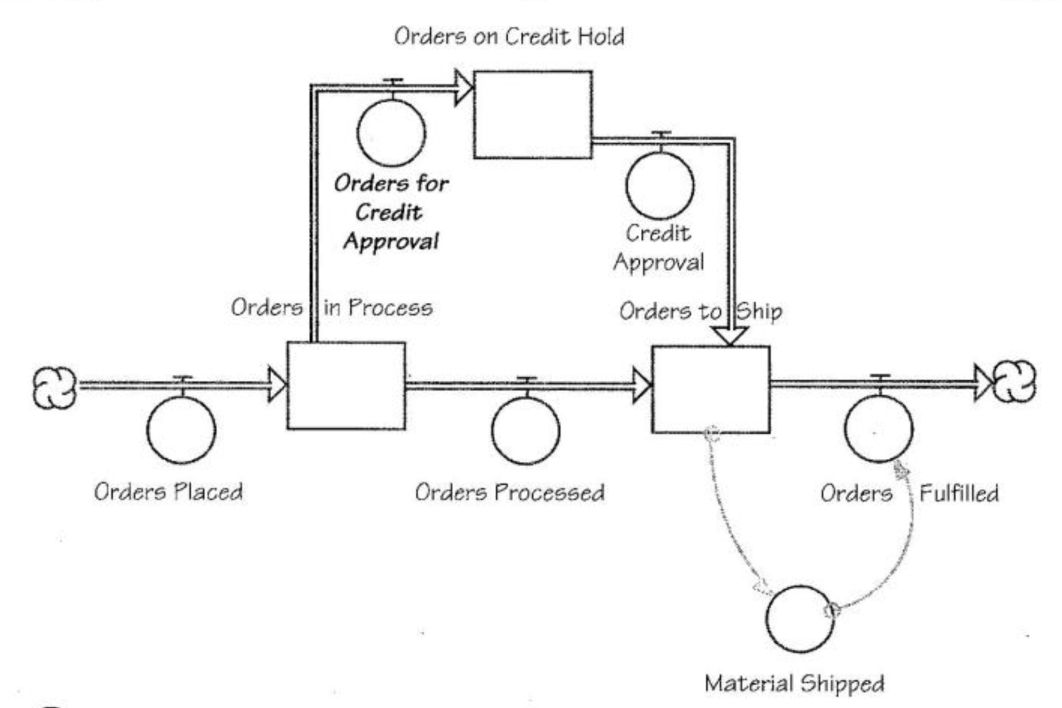

But where did those orders that contained incomplete or incorrect information go? What was missing from the original picture was another accumulator and flow that linked “Orders in Process” and “Orders to Ship” (see “Credit Bypass”). One significant category of “incomplete” orders consisted of those that required credit approval. These orders flowed from “Orders in Process” and accumulated in “Orders on Credit Hold” until they were resolved and passed on to “Orders to Ship.” Because these orders were considered “processed” by the customer order processing system, they did not show up as a problem there. If the flow into credit was small or the “Credit Hold” delay was not too long (i.e., the size of the “Orders on Credit Hold” accumulator was small), it wouldn’t have been much of a problem. But the number of orders on credit hold was becoming a significant percentage of the order flow, thereby affecting the overall delivery time.

Credit Bypass

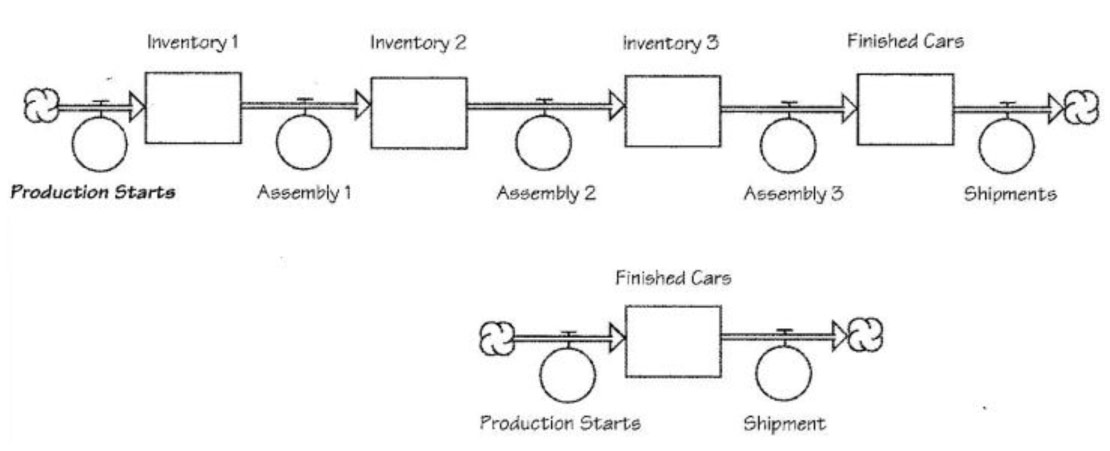

Just-in-Time Flow System

Once a “hidden” accumulator is identified, the accumulation can be reduced by focusing on the inflows and/or outflows. (Since accumulators simply convey information about the state of a system, whereas flows indicate actions being taken, the only way to affect the state of a system is by changing the flows.)

In the case of the semiconductor manufacturer, the leverage was to focus on the criteria that determined when orders needed credit approval, and to streamline the credit approval process itself. Upon further investigation, they discovered that 90% of the orders diverted for credit checks were approved, suggesting that more orders were being run through the credit office than was necessary. By changing the approval criteria on credit orders, they were able to reduce the flow into the “Orders on Credit Hold” accumulator and dramatically reduce the overall delay.

“Collapsing” Accumulators

In general, we can think about reducing delays as a process of identifying and “collapsing” accumulators. For example, Toyota’s Just-in-Time system removed the buffer inventory at each production step and thus converted a multistage, semi-coupled production process into one continuous flow system (see “Just-in-Time Flow System” on page 7). In essence, they eliminated all the accumulators in the process between production starts and finished inventory.

When trying to reduce delays in any process, you may want to follow these steps:

1. Map out your current process by identifying all the significant accumulators and flows.

2. Check for “hidden” accumulators by investigating the outflows of each accumulator to make sure that they balance with the inflows to the accumulator and the accumulator itself. (For example, if 10 cows flow into a pasture, but the total number of cows in the field at the end of the day is 2, the flow of cows back into the barn should be at least 8. If it is less than that, there must be another outflow somewhere — like a hole in the fence!)

3. Explore why flows are being diverted to other accumulators. Could policies or processes be changed to reduce those flows?

4. Focus on the outflows from the “hidden” accumulators. Are there changes that could be made in policies or procedures to increase those flows?

The End Result

Hidden accumulators may be chewing up valuable time and resources without anyone being aware of them. By identifying and eliminating as many accumulators as possible, you can work toward creating a process where every stage is directly contributing to the value creation chain.

Daniel H. Kim Is co-founder of the MIT Organizational Learning Center and of Pegasus Communications. Inc. He is a public speaker and teacher of systems thinking and organizational learning.

Editorial support for this article was provided by Colleen P. Lannon.