Etion line may churn out three different car models in 10 different colors. Sounds inefficient, doesn’t it? At the very least, Toyota’s shop floors must use an elaborate, centralized cost accounting system to set targets and track variances, right? Wrong. You won’t find banks of computers on the manufacturing floor telling Toyota’s production-line workers what to do next. Rather, employees determine that for themselves — and then accomplish it with minimal cost, time, and errors.

MANAGING BY MEANSOR RESULTS

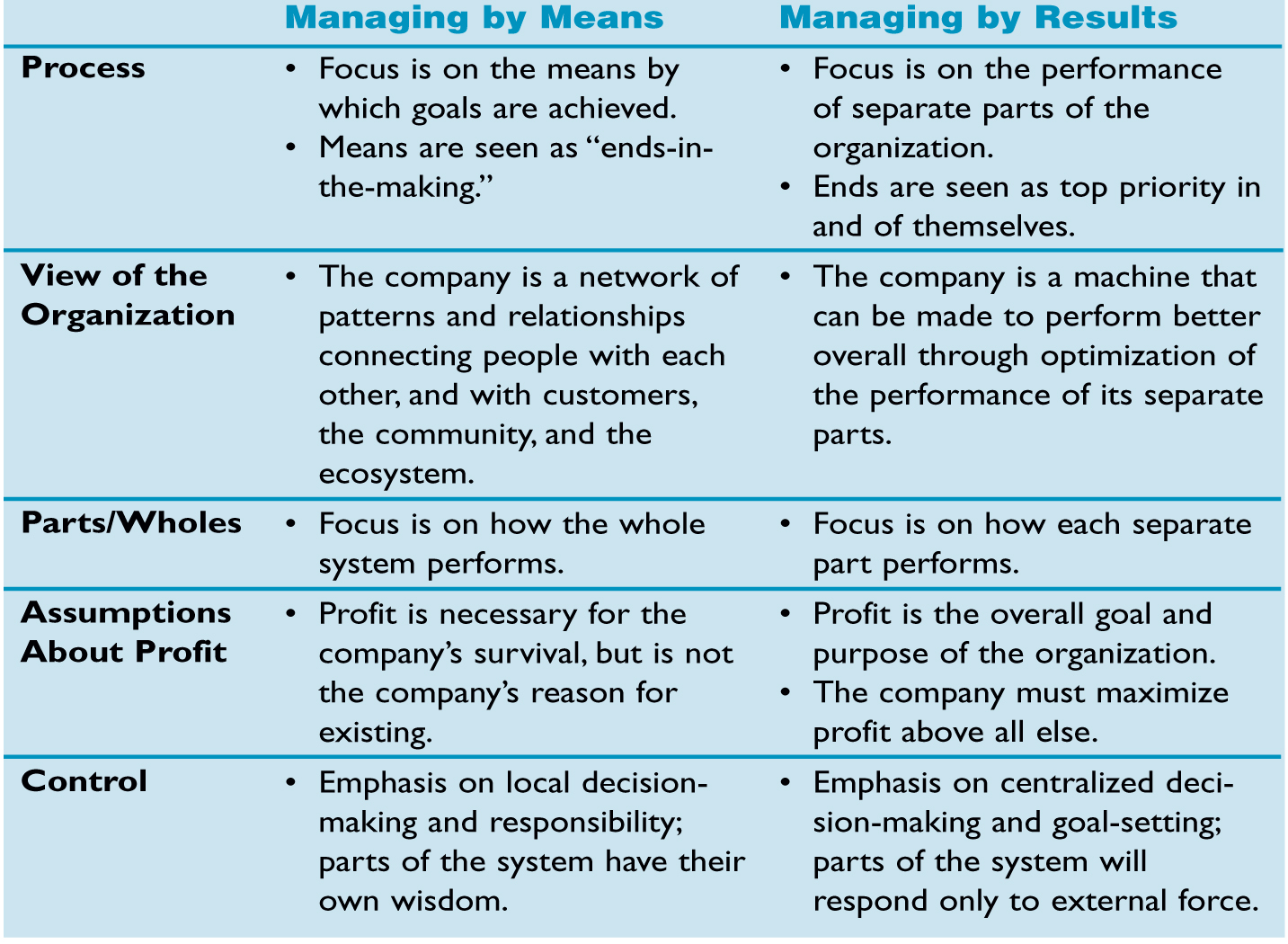

Companies that take this approach are practicing “management by means” (MBM). That is, they design production systems according to precepts that guide all living systems, including:

- self-organization, particularly an ability to identify “self by local rather than central control,

- an emphasis on the relationships among all parts of the organization, and

- the generation of diversity.

Managing by means contrasts sharply with the approach that most businesses follow, called “managing by results” (MBR). With MBR, firms use centralized decision-making to establish abstract quantitative targets for each part of the organization (for instance, “We’ll crank out 250 red widgets on this production line every hour, with zero flaws”). Moreover, decision-makers at these organizations attempt to control the company’s various parts as if the whole thing were a machine (see “Managing by Means or Results?”). Typical MBR control structures include:

- activity-based costing (ABC)

- activity-based management (ABM)

- performance measures to motivate individuals or teams, and

- material requirements planning (MRP) to control operations.

Compared to practices shaped by conventional cost-management thinking, management by means generates far less waste, higher efficiency, lower overhead costs, and more diverse outputs — all the qualities you find in natural, organic processes. In fact, if we look at a living ecosystem — a forest, for example — we see startling efficiency and diversity. Each part of every tree, such as the root system, consumes only the resources it needs to perform its function; in this case, delivering water and nutrients to the rest of the tree. Whatever waste is created, such as the oxygen that results from photosynthesis, is used by other systems connected to the tree within the same ecosystem. So, humans and animals take in the oxygen that trees produce as waste. And throughout evolution, nature has generated virtually unlimited varieties of shapes, sizes, colors, and textures in trees as well as in other living systems.

What does MBM look like in a business setting? Let’s take a closer look at one of the living-system principles that guide MBM — “local control” — to find out. Organizational learning expert Peter Seng explains local control by using a simple analogy: If you cut your finger, your body does not send messages to your brain for permission to act. Rather, your circulatory system generates coagulants near the injury, which flow immediately to the cut. Likewise, at Toyota, everyone who stamps, welds, paints, and assembles cars is guided not by a centralized scheduling system but by one aim: to meet the needs of their direct “customer” the person to whom their work flows next. Materials move smoothly from person to person, with minimal waste. And if workers encounter a problem, they immediately signal for consultation and assistance, never allowing a defect to pass on to the next worker.

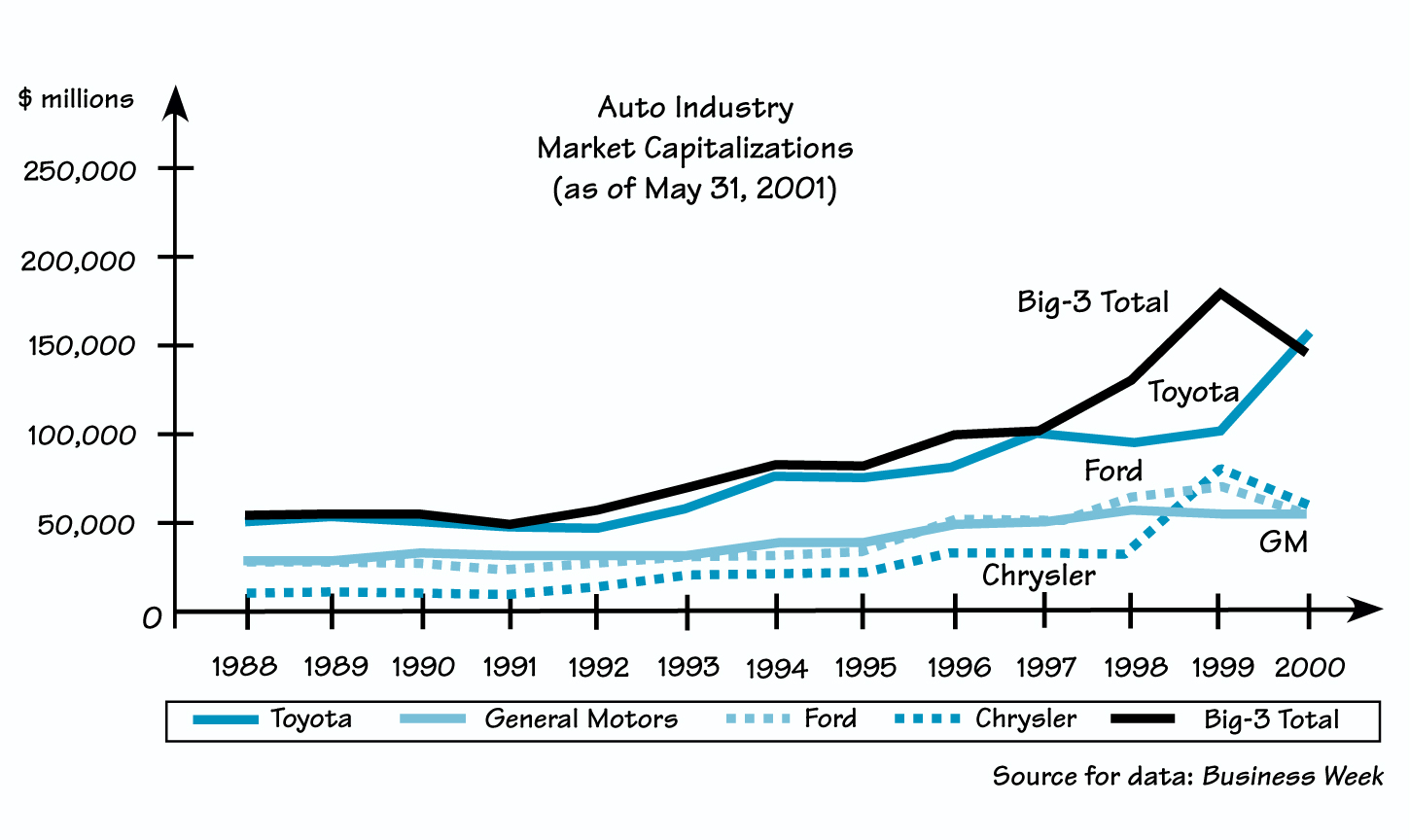

MBM can pay big dividends for companies that adopt it. Consider Toyota’s experience: Since 1960, the company has never had a loss year, nor has it ever teetered on the brink of bankruptcy — unlike many of its competitors. Moreover, market capitalization data reveal that Toyota’s market value rivals — and sometimes surpasses — that of the American “Big Three” auto makers combined.

Clearly, MBM offers important advantages over MBR. Yet, most companies continue to organize work according to MBR principles. Why?

The Big Lie

Companies that use MBR have bought into the “big lie” a simple assumption that sounds reasonable on the surface but that makes little sense when you look at how it actually plays out. This big lie is this: You can change the total cost or total profit of your organization by a certain amount by changing the costs or profits of the company’s parts by the e amount. In other words, because the total cost or profit of an organization presumably equals the sum of the costs or profits in parts, the total can be changed in any amount simply by changing its parts in the same amount.

Let’s take a closer look at that last point. This idea — that you can change the magnitude of the whole simply by changing parts in the same magnitude — is everywhere. Open any management accounting, finance, or economics textbook currently in use in MBA programs, and you’ll see this assumption implicit in any discussion about cost management. People actually believe that if they want their company to show an increase in profits of $1 billion, then all they have to do is cut $1 billion from somewhere in the firm. Perhaps they should sell off a division or outsource a major function. The idea is that, by treating the company’s parts as pieces that you can move in or out of the system like game pieces, you can influence the overall organization’s performance in absolutely predictable ways.

To be sure, you can do that with most machines. But with living systems — and human organizations are living systems — trying to optimize the whole by optimizing the parts only leads to declining performance. Still not convinced? Imagine a top-notch basketball team. Now think about what would happen if each player tried to optimize her individual performance by scoring as many baskets as possible during a game. What would happen to the team’s ability to function as a smoothly running, coordinated team? If you envisioned a chaotic mess easily bested by the opposing team, you understand the danger inherent in this assumption about optimizing parts of a natural system.

Where did this mechanistic way of treating human systems come from? In the West, the idea has a long history. Galileo, the 16th century Italian astronomer and physicist, first introduced the concept of separating the idea of motion from a moving object itself — and then measuring that motion. He came up with this idea as a way to address anomalies in moving objects that existing theories inherited from Aristotle couldn’t explain. After the 16th century, Westerners began trying to quantify everything. As Galileo’s thinking was further developed by Rene Descartes and then Isaac Newton, Westerners began seeing the world as a set of independent objects. They defined the characteristics of these objects by absolute measures and believed that it was only external force or impact, not embodied patterns in a web of relationships, that moved these objects.

When Actions Backfire

Today, management science still draws from the mechanistic worldview. But when you treat organizations as machines, you behave in ways that ultimately keep you from achieving your original goal of improving company performance to its full potential.

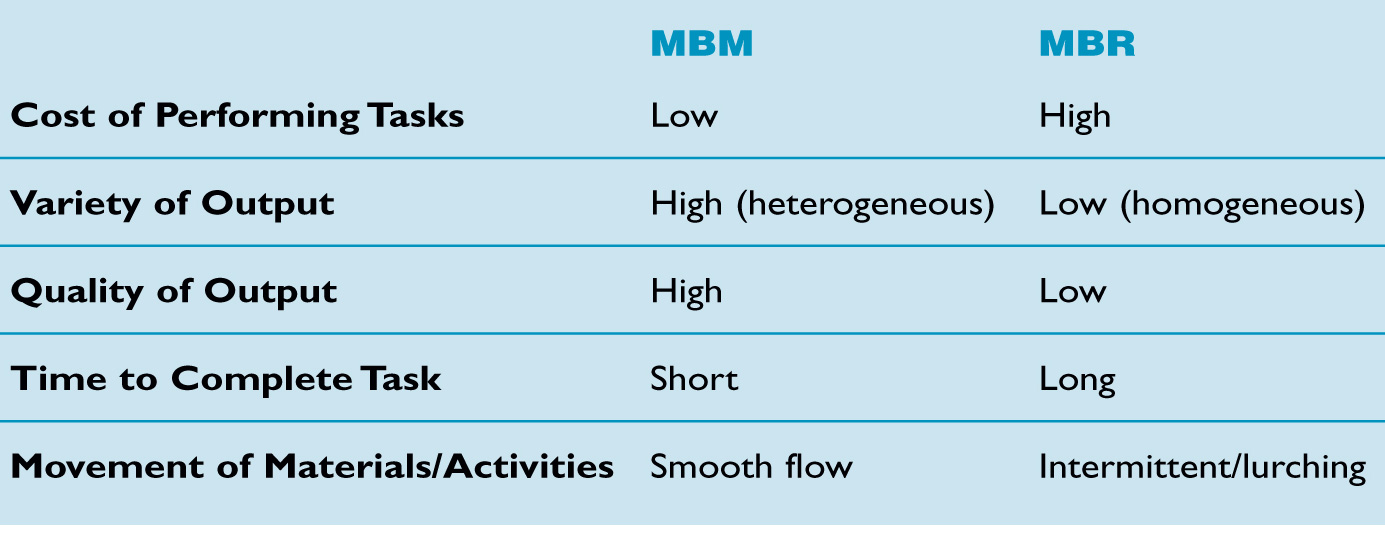

“Working Harder.” Companies that manage by means achieve a simplicity that lets each step in the production process move forward cheaply, quickly, and with high quality. But when you believe the big lie, you “work harder” in each of the organization’s parts in order to “improve” performance in the whole. What does working harder look like? To force better performance in each part of the organization, you create imbalances among parts and systemic delays that cause you to build an elaborate infrastructure — processes for scheduling, expediting, controlling, reworking, and so forth. In other words, you make things complicated.

Thus, companies that manage by results create complication, which clogs up the workflow with waste, delays, and high costs. This degree of complication gets costly in terms of the people and other resources required to run this infrastructure. Indeed, accountants call this cost “overhead” or “indirect cost.” In many companies, this cost amounts to as much as half of all the costs incurred by doing business.

Higher costs in turn prompt you to produce a smaller variety of products or services in an effort to control those costs. After all, it takes enormous energy and effort to create variety. Companies that emphasize MBR often try to do things as homogeneously as possible; that is, they resort to mass production in order to streamline costs and processes. But in an age of increasingly complex customer demands, mass production isn’t the kind of response that’s going to endear a company to its external customers.

Complication increases the time required for work to move from one destination to another. And when work does move from stage to stage, it progresses intermittently. It lurches along rather than flowing smoothly and effortlessly. Quality also suffers when things get complicated. If you define quality as giving customers what they want, when they want it, and how they want it, it’s hard to achieve all that when you’re grappling with a complicated order-delivery system.

All told, performance drops rather than improves with MBR. If we compare the costs and benefits of MBM and MBR, the differences between the two approaches are striking (see “The Advantages of MBM”).

Working Separately. The big lie also causes you to treat each part of the company as a separate entity. Departments arise in which people work independently of each other. Indeed, people in the various departments, or functional “chimneys,” may even feel indifferent to what folks do in other departments.

In such an arrangement, work comes together only through the vast array of infrastructures that have been created to collect and combine materials or information. Although people in the various departments may all be doing useful, valuable work, the system itself — the organization — doesn’t help the work flow from stage to stage in a smooth, continuous way.

The Big Truth

In truth, you can’t optimize a whole organization by trying to optimize its parts. That’s because in natural systems, the whole doesn’t equal the sum of its parts. We hear that phrase often — but what does it really mean for human organizations?

Because organizations represent an individual human system writ large, let’s see what happens when we compare the value of a whole human being with the value of his or her individual parts. If you disassembled a person into all the molecules that make him up and removed the water that constitutes most of any human being’s cells, what you’d have left wouldn’t weigh more than a few pounds. And, it wouldn’t be worth more than about 50 cents on any market. If you took things one step further and broke those few pounds of molecules into the atomic particles that make them up, you’d have a pile of “stuff” so tiny that you couldn’t even see it with the naked eye.

Now imagine doing something similar with a business. Picture adding up the value of all the separate parts of the business — the equipment, the supplies and inventory, the cash, the building, even the human beings who work there. The dollar amount that you come up with won’t be anywhere near the actual value of the organization when it’s working as a system — that is, when the relationships among all those parts are functioning. The value of the overall organization comes not from its various parts but from the way in which those parts interact. Thus, it is because of those relationships that the whole is worth far more than the sum of its individual components.

Moving from Managing by Results to Managing by Means

So how can your organization avoid the pitfalls inherent in MBR and reap the benefits offered by MBM? It’s not easy. You have to look at work through a radically different lens. Put another way, this change requires you to stop trying to identify better answers and instead ask a new question: What would your organization be like if it ran according to the principles that guide natural systems?

Here are three provocative ideas to get you started:

Nurture Relationships.

If you ran your organization according to natural systemic principles, you would stop trying to optimize performance in the company’s individual parts in order to improve the overall organization’s performance. Rather, you would try to improve the quality of the relationships among the parts.

THE ADVANTAGES OF MBM

For example, you might take steps to channel the flow of information and material into direct pathways between employees whose work interconnects. Ideally, each worker would hand material directly to the next worker in response to a signal from that worker. Where distance in space or time makes direct flow impossible at the moment, workers might use indirect signals, such as empty slots in a rack or order cards. But the goal should be to replace such tools with ways to make it easier for the “upstream” employee to see what the “downstream” employee (his or her “internal customer”) needs.

By having work follow standardized procedures as well as having it flow along direct pathways from worker to worker, you ensure that any problems that arise are visible to people as soon as they occur. This instant, widespread feedback lets people respond immediately to problems and play a direct role in their resolution. In addition, you would make sure that all material flowed at the rate demanded by the customer (whether internal or external). Work should not lurch from stage to stage at varying rates. When it does, the company needs places to store backlog and processes to keep track of it. Expenses start mounting. And whenever material and information come to a standstill, the delay reverberates all the way along the rest of the work path. It’s impossible to deliver quality — giving customers what they want, when they want it — under conditions of uneven or intermittent flow.

Management expert Dr. W. Edwards Deming emphasized the importance to quality of building proper relationships in organizations including always knowing how every customer connects with every worker. Deming suggested a powerful exercise to demonstrate where you need to clarify and strengthen relationships in your organization: Ask everyone to stand up and grab hold of the hand of the person who supplies them with whatever it is they need to do their work. Now ask them to take their other hand and grab hold of the person who needs something from them to get their work done. According to Deming, if your workforce can’t do that, your company is suffering from serious disconnection.

Another management visionary and poet, Judy Brown, offered a compelling image of the importance of relationships in MBM. Brown describes building a log fire. The flame comes from the logs, she agrees, but simply jamming logs together won’t generate a flame. To get a good, strong fire, you have to pay attention to the spaces between the logs. If you stack the logs too tightly, the flame may start, but it’ll sputter out quickly owing to lack of sufficient oxygen. If you stack the logs too loosely, the flame will never get started. To get the flame just right, you have to stack the logs just right. That flame is like the performance an organization is able to achieve, and those spaces between the logs are like the relationships between the people and other components in an organizational system.

Take a Long-Term Focus. While MBR tactics can boost financial performance for short periods, they invariably lead to more unstable and inferior performance in the long run. A company that runs according to principles that guide natural systems will enjoy long-term results that are more stable and more satisfying than the results recorded by a company that runs according to MBR principles. This difference is portrayed in a graph of the performance of two hypothetical organizations — Company A (run based on MBR) and Company B (run based on MBM) (see “Stability Vs. Drama”). To evaluate the two companies’ performance, the graph plots performance over several business cycles, using traditional financial metrics, such as operating income, operating profit, return on investment, and so forth.

In this graph, Company A shows a variable, unstable performance pattern. Company B’s performance pattern varies much less; overall, this firm seems much more stable. At first glance, Company B’s performance looks kind of lukewarm. The firm never loses money, but it never achieves the kinds of peaks that Company A does. However, Company B always does reasonably well. Indeed, in the long run, its average results may prove better than its competitors’.

Toyota is an example of a Company B enterprise. Its long-term financial performance is less variable and, overall, less “exciting” than that of its competitors. In times of peak prosperity, its bottom-line returns seldom garner the attention the press often pays to its competitors’ soaring profits. But during recession periods, it never suffers negative returns.

Differences in accounting conventions make it difficult to unambiguously compare Toyota’s average long-term profitability with that of the American auto makers. However, stock market capitalization data indicate that Toyota earns a consistently higher average level of profit than any of its competitors. Indeed, annual data compiled since 1988 show that Toyota’s “market cap” exceeds the market cap of every one of the American “Big Three” auto makers in each year, and it equals or exceeds the combined market cap of the Big Three in three of those years (see “Toyota Vs. the Big Three”)!

Support a “Multicellular” Organization. In a “natural” organization, work follows a simple and straightforward path. Orders come in, and products go out. That’s it. How does this happen? Everyone in the company functions as an essential part of a multi cellular organization: They each figure out what they need to do to satisfy their customer — whether it’s someone within the company to whom their work flows next or someone outside. The flow of work through the entire system resembles that of the metabolic flow through the cells in a tree or in a human body. Moreover, the rate of that flow is dictated not by centralized control mechanisms, but simply by what the customer wants, in the time he or she wants it. As a result, work flows at the same rate among all the cells of the “organism.”

Thus, rather than looking to financial controllers, cost accounting procedures, and computers to tell them what to do next, employees in a natural organization look to the flow of work itself — at every step in the value stream — to determine what needs to be done. The work itself gives them all the information they need. To have the information that guides work be present in the work itself is not possible, of course, until the work flows more or less continuously from hand to hand. Connecting work in a continuous flow is how a company begins to free its operational information from bondage to computer control systems.

To run your organization according to the principles that guide living systems, you may well have to let go of old assumptions and adopt challenging new ones. But as Toyota has proven beyond question, the payoff makes the effort worthwhile. Indeed, Toyota’s example shows that treating the means as “ends-in-the-making” is a much surer route to stable and satisfactory financial performance than to continue, as most companies do, to chase targets as though the means do not matter.

TOYOTA VS. THE BIG THREE

Stock market capitalization data indicate that Toyota earns a consistently higher average level of profit than any of its competitors. Indeed, annual data compiled since 1988 show that Toyota’s “market cap” exceeds the market cap of every one of the American “Big Three” auto makers in each year, and it equals or exceeds the combined market cap of the Big Three in three of those years.