“No matter how hard Western nations try to engage in Quality Control education, they may not catch up with Japan until the 1990s, since it requires ten years for the QC education to take effect,” quality expert Dr. Joseph Juran warned in 1981. Ten years later, Juran’s prediction seems overly optimistic. Japanese companies passed the West in the quality marathon sometime in the 1980s, and they show no sign of slowing down.

Juran’s message is all the more ominous if we consider Analog Devices President Ray Stata’s theory. He believes that, contrary to the Boston Consulting Group’s learning curve theory, “learning, properly managed, occurs as a function of time, independent of cumulative volume.” The implication of his statement is startling: we will never catch up with the Japanese because they have a permanent head start on us. In other words, we can’t expect to win the quality race by simply imitating the Japanese; we must innovate and improve upon Total Quality Control.

Integrating TQC and systems thinking can accelerate organizational learning beyond the current capabilities of TQC methods. The two approaches form a synergistic pair whose individual strengths complement each other and provide a balance of learning at all levels of an organization. Used together, they can help build a shared understanding of both conceptual insights and operational processes, forming a powerful new management paradigm I call Systemic Quality Management (SQM).

Beyond TQC: Systemic Quality Management

To be lasting and significant, organizational learning must advance on both the operational and conceptual level. Operational learning means improving behaviors or ways of doing things — changing a machine setting, for example — in order to enhance the performance of a particular system. Conceptual learning involves changing one’s mental models about how the world works, such as reframing a problem in a different context and exploring the implications. Learning at one level without the other is like trying to run a race with one foot nailed to the starting line — you may get off to a quick start, but you won’t go very far.

“…we can’t expect to win the quality race by simply imitating the Japanese; we must innovate and improve upon Total Quality Control.”

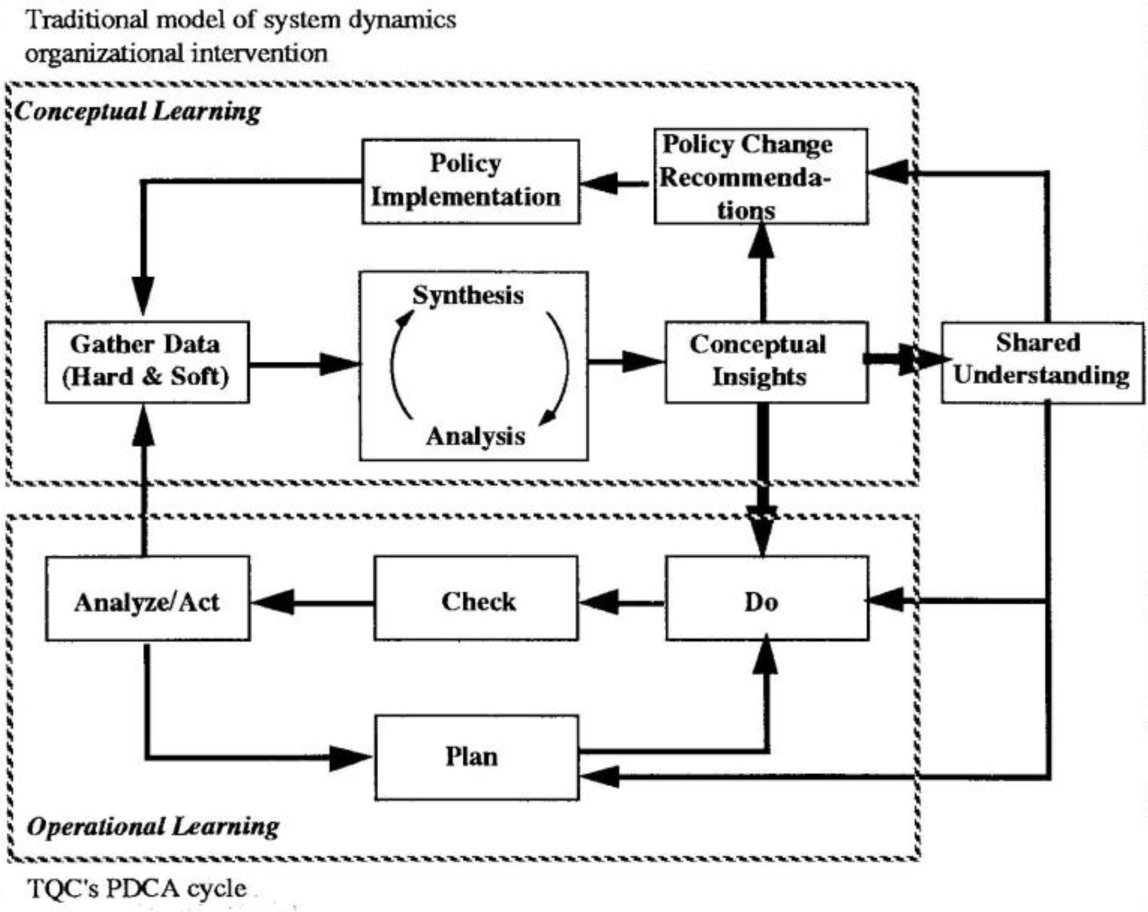

The Systemic Quality Management (SQM) model (see “SQM Model” diagram) combines systems thinking, with its conceptual basis, and TQC, with its operational emphasis, into an integrated management paradigm. The top dashed box of the SQM model represents the traditional system dynamics problem-solving approach of gathering data, articulating the issues involved, building a model, running simulation analyses, identifying leverage points, and proposing policy changes. An implicit assumption of this process is that the insights generated will be compelling enough to produce action. In reality, however, policy change recommendations are not always implemented due to a lack of strong operational methods such as those TQC provides.

The bottom dashed box shows a typical TQC quality improvement process — the PDCA (Plan-Do-Check-Act) cycle. Requests from upper management are translated into a plan of action and checkpoints are determined for monitoring progress. The plans are then incorporated into the budget cycle and implemented. Any deviations found at the checkpoints are analyzed, and actions are taken to correct any discrepancies. Although the PDCA cycle works very well in implementing strategic plans and maintaining control over current processes, it is relatively weak where systems thinking is most helpful — identifying the high leverage areas that drive the whole process.

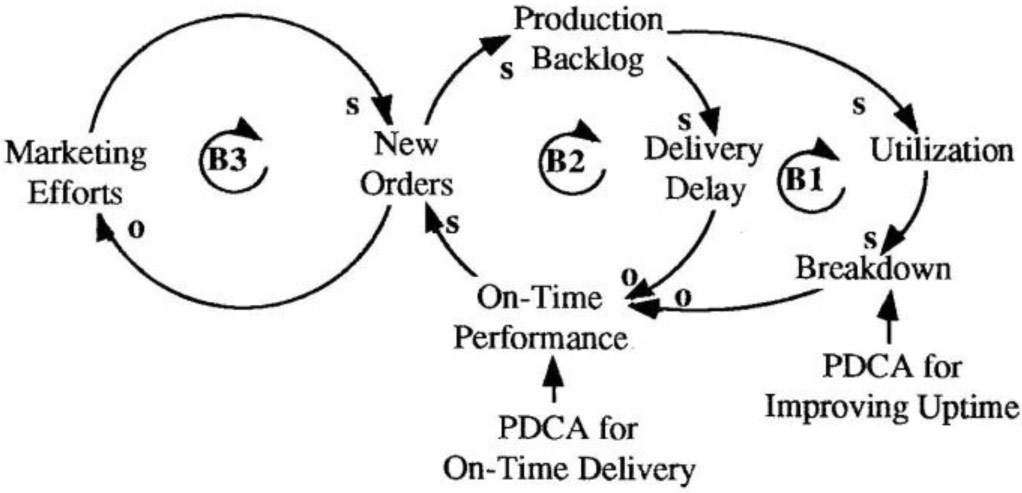

Systemic Quality Management blends the conceptual strength of systems thinking and the operational focus of total quality into a seamless process. In a manufacturing environment, for example, the PDCA process could be helping line workers gather data, plot and analyze them, and determine how to make improvements to reduce equipment downtime and increase on-time delivery performance. A systemic study may reveal, however, that the timing of marketing efforts and production schedules systematically produces demand/supply imbalances, creating periods of deteriorating delivery performance (see “Marketing-Production Connection” diagram). The real leverage may lie in coordinating the activities of the two functions by building a shared understanding of how the two are interdependent.

SQM Model

The Strategic Quality Management (SQM) model fuses the conceptual strength of systems thinking (top) and the operational focus of total quality methods (bottom) into a seamless process.

The Systemic Quality Management model emphasizes the importance of creating shared understanding about the whole system. Building shared understanding through the use of systems thinking tools such as management flight simulators and learning labs can enhance the PLANning and DOing steps of the PDCA cycle by providing a common base of conceptual models. The analysis and action produced through the PDCA cycle can, in turn, generate new data which would feed into the data gathering process and the next cycle of the PLANning stage. By fusing these two methodologies, Systemic Quality Management provides an integrated and balanced approach to organizational learning.

TQC as a Vehicle for Organizational Learning

TQC’s contribution to organizational learning is strongest on the operational side. But TQC is not just about improving production steps and reducing cycle times — it is a thought revolution in management. TQC has forced managers to abandon old mental models of viewing quality/cost and quality/productivity as either/or decisions. It is also changing managers’ definition of quality from conforming to specifications to satisfying customers’ needs.

The concept of building-in quality rather than inspecting-in quality has prompted a major shift in the way managers once viewed the production process. This change in the prevailing mental model has driven solid achievements at the operational level: statistical quality control (SQC) has improved quality and lowered production costs through smaller variances and reduced scrap rates; separate quality inspectors are becoming obsolete as workers learn to inspect their own work for defects; and a customer-oriented approach has increased customer satisfaction.

As quality steadily improves at companies using TQC, there is no doubt that a great deal of learning continues to take place at the operational level. But beyond the initial mental breakthrough required at the outset of instituting TQC, new learning opportunities at the conceptual level become less available. Managers can go on advocating improvements within the current framework of organizational policies and traditions without gaining much insight about the whole system.

Systems Thinking and Organizational Learning

Unlike TQC’s more operational focus, systems thinking’s underpinnings are conceptual in nature. Systems thinking advocates approaching problems from the basis of the whole, rather than reducing problems to individual pieces and trying to understand each part. Whereas TQC focuses on analyzing the separate parts that make up the whole, systems thinking strives to synthesize the constituent parts.

Systems thinking helps break through functional walls in organizations by providing a framework for understanding the importance of managing the interconnections between various functions. Systems thinking is also useful for gaining deeper insights into the nature of complex systems, finding leverage points within the system, and testing assumptions about the viability of various policies.

By emphasizing the importance of trying to understand a problem, not simply solve it, systems thinking attempts to transform problem-solving organizations into learning organizations. A learning organization is one that consciously manages its learning processes through an inquiry-driven orientation among all its members. That is, learning organizations actively and explicitly encourage both operational and conceptual learning to ensure that areas of strategic importance are not neglected.

Building a learning organization means continually developing the capacity to create one’s vision of the future. In order to design and implement effective policies and achieve desired results, managers need to look at their organization and its environment as a unified system. A systems perspective makes it easier to pinpoint the high-leverage actions that will produce significant, long-lasting improvements. But acquiring such an understanding will require ongoing management education that trains managers to blend analysis and synthesis into a new style of thinking. As they do, managers will begin to take on new roles and acquire new skills.

Marketing- Production Connection

A successful marketing campaign produces a bulge in orders, swamping the factory. The factory starts to run at maximum capacity to get the orders out the door, but on-time performance suffers (BI). New orders fall as customers experience long delays (B2). As new orders slow down, the factory is able to improve on its delivery performance. But in the meantime, marketing has decided to launch a new campaign to counter the fall in new orders (83), starting the cycle again.

Researcher and Theory-Builder

In learning organizations, managers will be responsible for enhancing the quality of their thinking, not just the quality of their doing. This means becoming theory-builders: creating new frameworks for continually testing strategies, policies, and decisions. It will also require the skills and inquiring perspective of a researcher who is engaged in active experimentation.

Unfortunately, we usually think of experimentation in organizations as “Hey, I’m just trying something new so don’t hold me accountable,” or “Let’s see what happens.” In such a setting, there is little opportunity for learning. Real experimentation will mean that managers, as researchers and theory builders, will actively formulate hypotheses and conduct “controlled” experiments to test them. Systems thinking provides an array of tools for running such experiments. Two in particular are management “flight simulators” and learning laboratories.

Creating Learning Environments

The necessary elements for learning are a set of tools, a context for the learning, and a structured setting for conducting experiments. Baseball teams, for example, have their equipment, game rules, and practice fields. Airline pilots have flight simulators, air space grids, and simulated flight conditions. No team would dream of starting the regular season without practice games, nor would airlines risk multi-million dollar airplanes and the lives of hundreds of passengers in order for pilots to learn by trial-and-error.

Managers, on the other hand, do not have comparable tools and environments for experimenting and learning — in management, initiation by fire is the rule. However, management flight simulators now offer managers the equivalent of a pilot’s flight simulator, so they can experiment with various policies without fear of “crashing and burning” real companies.

Appropriately, the first management flight simulator developed at the MIT Sloan School of Management was based on an airline — People Express. Each entering class of masters students at the Sloan School spends a day developing their strategy and “piloting” the simulated airline (see “‘Flying’ People Express Again,” November 1990 for a more complete description of the simulator). Each team makes five quarterly decisions as the players struggle to manage the growth of the start-up airline. Spreadsheets, graphs, and internal management reports containing competitor and market information help them chart their progress. Through repeated trial-and-error experimentation, the students gain simulated experience managing the challenges of managing a rapid-growth company. People Express and other simulators are currently in wide use in academia as well as corporations.

If the simulator is analogous to a sports team’s equipment, the learning lab can be thought of as a manager’s practice field. Learning labs provide a structured learning environment where management teams can test out new strategies and policies, reflect on the outcomes, and collectively discuss the central issues. Managers can accelerate time by rapidly simulating a real life system and then stop the flow of time at each decision point to reflect on their actions.

By making operating assumptions explicit and testing those assumptions within the learning lab, managers are encouraged to reflect on not only the quality of their decisions, but how they arrived at those decisions. The learning lab environment promotes conceptual learning by helping managers develop an inquiry mode of learning — to continually “think about their thinking” and break away from outmoded frames and perceptions.

Just as TQC provided workers with methods for approaching their work more scientifically, systems thinking provides managers with tools and a framework for continually testing and improving their decision-making. By synthesizing these two methods into an integrated process, the Strategic Quality Management model captures the dual nature of managers’ new work — rethinking issues and testing the outcomes on a conceptual as well as operational leve1.