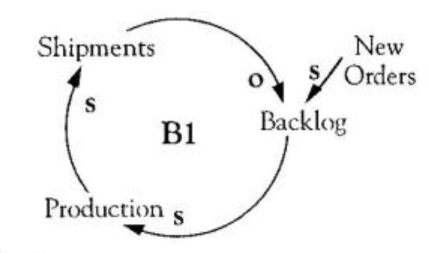

A simple balancing loop can be thought of as a basic control loop. In this type of feedback loop, any discrepancies between desired and actual states are immediately closed.

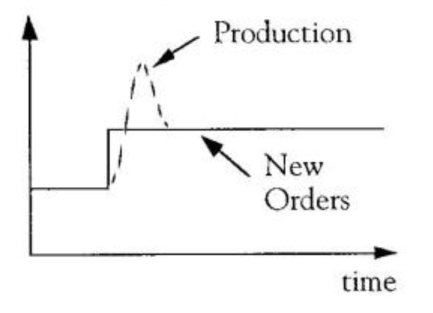

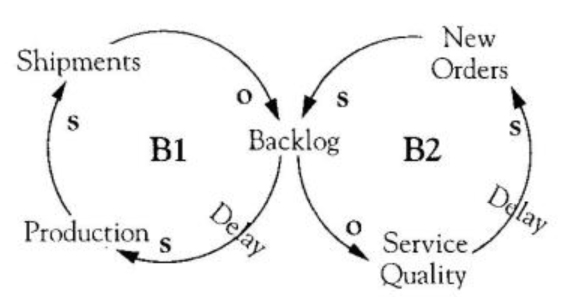

In a typical production setting, for example, a backlog represents a gap between new orders (desired) and shipments (actual). If there are no significant delays in the system, a production increase would lead to higher shipments, thereby reducing the back-log (B1). A graph of this system over time shows one blip in production to adjust to the higher level of new orders.

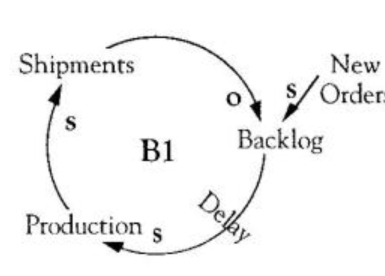

Delays in the Loop

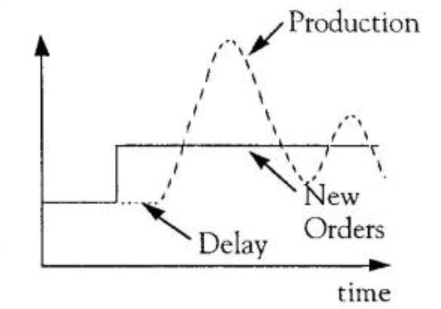

If, however, the factory is already working at maximum capacity, there will be a delay before production capacity can be increased. In the meantime, the backlog will continue to grow. When the new capacity comes on line, production can be ramped up to decrease the backlog. As production moves along, however, the backlog may be reduced to levels that are too low for effective scheduling, so production has to be throttled back. As the adjustments are made, the backlog may grow again, leading to another production adjustment.

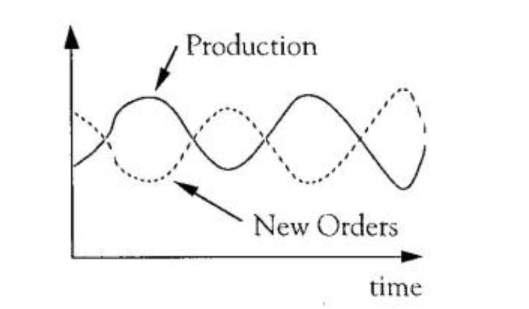

This oscillating behavior is common in most balancing loops with significant delays: the delay in response often means we overshoot our target and oscillate around the goal.

Coupled Loops

Of course, a loop rarely exists in isolation. In this case, the dynamics of the delay inherent in loop 51 may affect the quality of customer order fulfillment. The size of the backlog and the length of the delay in bringing more production on line may lead to a decrease in service quality, which, after yet another delay, may affect future business and the current order backlog (B2).

While the company is trying to work through the backlog, many customers may take their business elsewhere until the factory can be more prompt in shipping their orders. With fewer new orders coming in, production is able CO work off the backlog even faster, and after a while, the backlog becomes so small that the factory is able to ship faster than its competitors. This leads to a revival of new orders, which leads to higher backlogs, thus repeating the cycle as shown.

Complex Dynamics

Balancing loops coupled with delays can create complex behavior because there are so many different sources and sizes of delays. When you suspect that this structure is at work, it is helpful to identify and quantify the delays involved. If you can shorten the internal delays, you can achieve greater stability in your system. If you can’t shorten them, being aware of them will at least better prepare you to deal with the consequences of the delays.

TIP: A “boom and bust” phenomenon often signals the existence of balancing loops with delays. If you suspect such a dynamic is at work, by to identify and quantify the key delays in the system.

Drawing balancing loops with delays can help you begin to identify explicitly the delays that may be affecting other processes. It is important to remember, however, that causal loop diagrams are not meant to show the kind or lengths of delays; for that you would need to map out accumulator and flow structures and translate them into computer simulation models. Identifying where delays exist, however, is an important first step in gaining insight into your system’s behavior. Further reading: “Delays: Accumulators in Disguise,” Volume 2, Number 5 (June/114 1991).