During the mid-1980s, a large high-technology company launched a project to begin thinking more systemically about strategy. “COPEX” (a fictional name) designed, manufactured, sold, and serviced a product that was essential for most businesses. The company, however, was feeling financial pressures — the most dramatic of which were experienced by the Equipment Servicing Division, which contained the company’s largest workforce.

The division was in serious financial trouble. Up until then, it had been coping with its financial problems by cutting positions, which seemed to improve profits temporarily. Now, faced with new pressures, it seemed obvious to the financial group within the division that it was time to cut the workforce again. Others in the division, however, felt that downsizing was exactly what the company did not need to do. This group argued strongly that improving service quality was the solution to their financial woes.

When representatives from these two conflicting groups were brought together, the debate became almost hostile. It was clear that the issue of downsizing was painful to both sides. Because of the need to explore this topic further, our consulting team was invited to work with members of the division using a systems thinking approach.

Fragmented Views

We started the project work with a one-day training session for a cross-functional group of managers from the division. During the segment on systems thinking, we drew causal loops that explored the issues of downsizing and service quality in the Equipment Servicing Division, including a “Fixes that Fail” diagram (see “Downsizing that Failed?”). The central question that emerged from this session was whether the financial gains from downsizing would be offset by a decline in service quality, and ultimately a decline in sales.

To explore this question further, we decided to rake the next step and build a computer model. The first model we created was very simple, and was used in a series of small group sessions to help the managers become comfortable with the modeling software and with the basic dynamics of the system (see “Downsizing and Service Quality Model,” p. 10). The modeling tool we used was ithink’s predecessor, STELLA, which was used without any other interface.

The small group sessions were helpful in clarifying the assumptions behind the two contradictory views of the business. For example, when the VP of Finance — a lead supporter of the downsizing — tested his approach in the model, he was puzzled to see the financial situation continue to slide. When he reflected on this surprising result, he was finally able to articulate his mental model: he believed that he could cut staff and that there would be no ripple effects—that everything would “stay the same.” The data he had previously used to support this position was that downsizing in the past had led to a temporary increase in profits. Although typically there was a later downturn in profits, he attributed this to competitor activity. Our model, however, had no active competition, and the downturn still occurred. Thus the model seemed to suggest that the decline in profitability could be due to the delayed effects of reduced service quality on sales. For the first time, the VP was forced to consider feedback within the system — the potential unintended consequences of a reduction in workforce (see “Unintended Consequences,” p. 11).

The promoters of improved service quality were equally fragmented in their thinking. They believed that if the division just added more people, quality would increase, and that would improve their revenue stream. They also had data to support their view — the company had discovered through market research that its service quality rated poorly compared to its competitors. However, when this group worked with the model, they found that adding people did improve service quality and sales, but with consistently unprofitable results. By ignoring the high cost burden of the increased service force, they too were assuming that you can change one aspect of the system and that “everything else stays the same.”

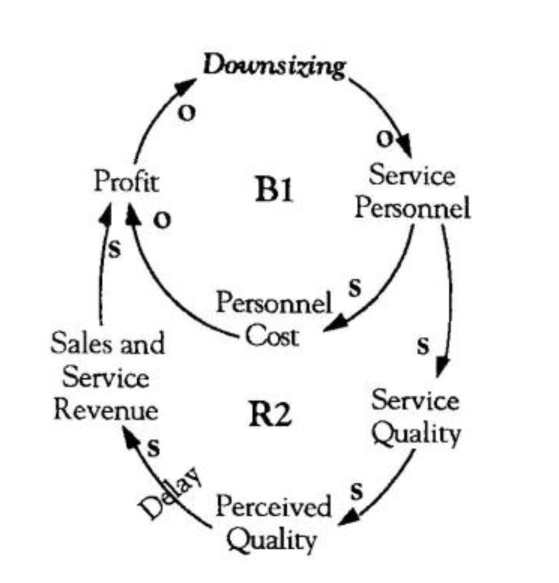

Downsizing that Failed?

To “fix” its ailing Equipment Servicing Division, COPEX had tried reducing the number of employees in the post, which decreased us personnel costs and improved profits temporarily (B1). But the drop in numbers of service personnel may have led to decreases in service quality, bringing sales and service revenue down and making profits fall even further (R2).

Learning and Leverage

After our small group sessions, we went on to create a second model that incorporated enough detail to represent some of the specific initiatives the division was considering. To work with this larger model, we brought the group together for a one-day session to consider various strategies for improving the business. As the group tested various alternative strategies, their level of understanding deepened. One compelling lesson that emerged was that any proposed initiative would not affect results in the short term, and thus the company would face continued financial pressure for the foreseeable future.

The most important insights, however, were about the fundamental architecture of the business. The reason that the original policies (lay off workers vs. add service capacity) failed to create a sustainable business was that the basic relationship between cost and revenues in this division was unworkable. For example, keeping enough personnel on hand to provide competitive service quality would cause an unprofitable overhead structure, but reducing personnel to a profitable level would yield low service quality and inhibit growth. The lesson was clear: it was impossible to achieve growth without a fundamental restructuring of the business line.

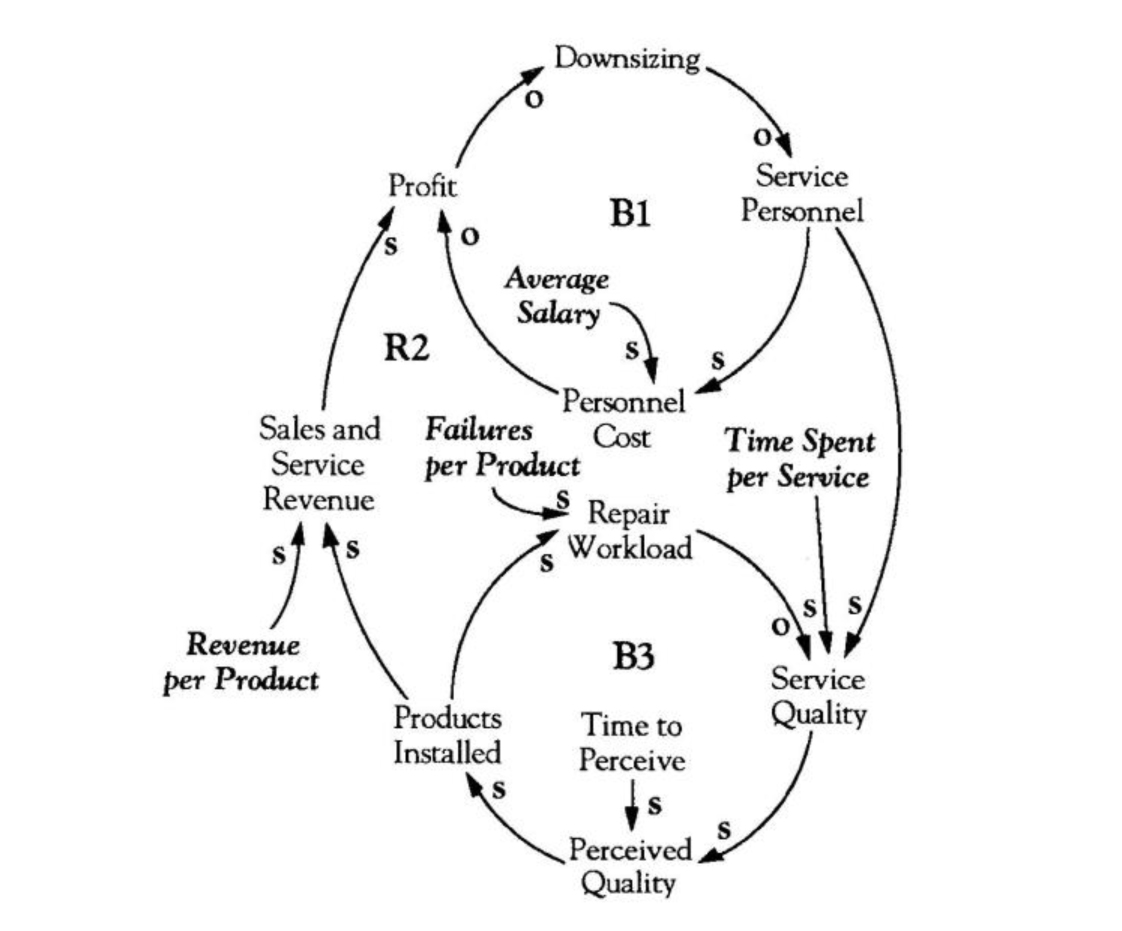

The real leverage for dramatically changing the business line was to modify any one of the basic parameters that determined costs and revenues, such as Revenue per Product, Failures per Product, Time Spent per Service, and Average Salary (see “Critical Business Parameters”). For example, a reduction in breakdowns would require fewer technicians per installed machine, which would decrease overhead and improve profitability while actually increasing service quality.

It is important to recognize that improving the breakdown rate was not the answer — it was only one possible structural change that would bring about the desired results that the group wanted.

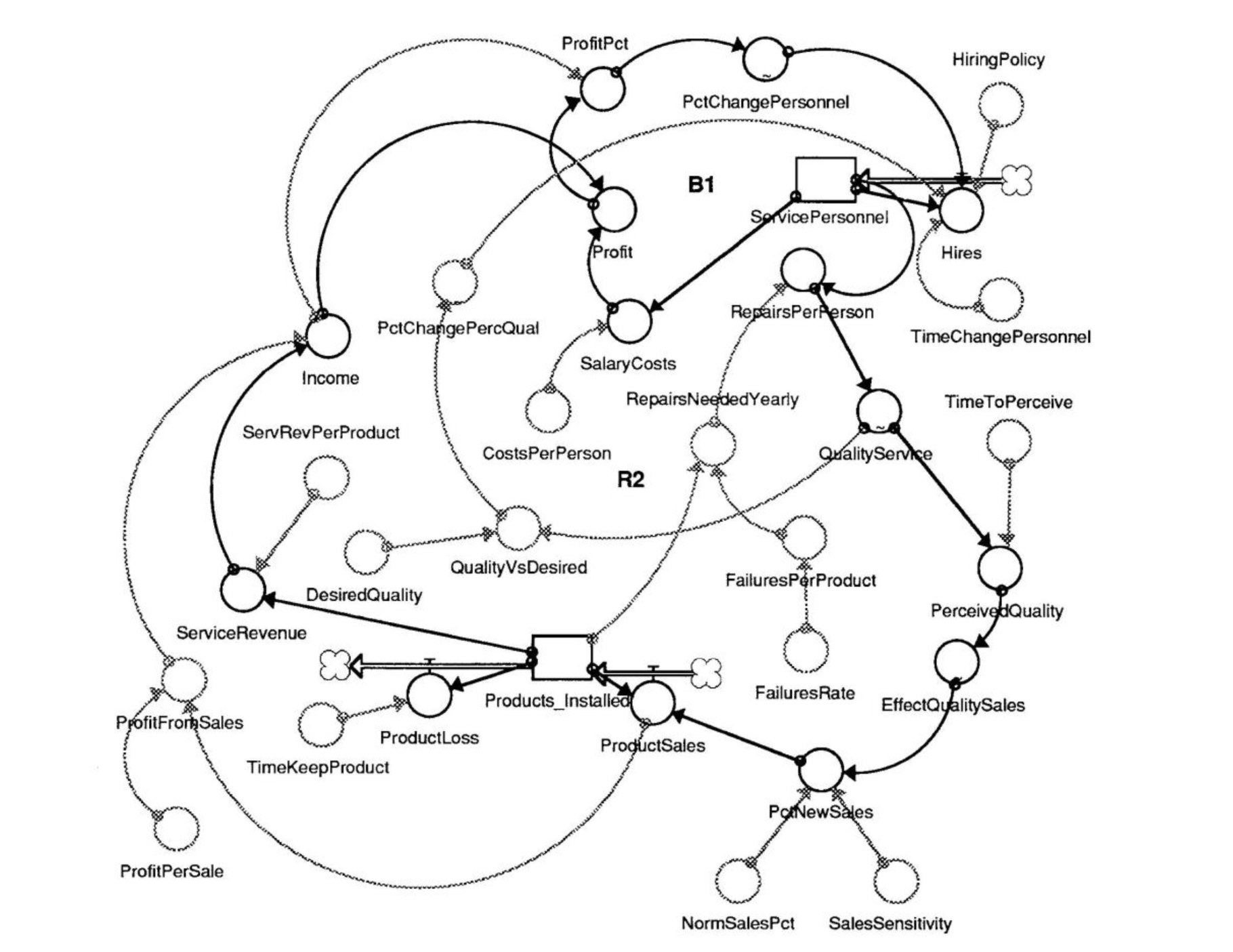

Downsizing and Service Quality Model

The initial computer model that was created for the Equipment Servicing Division was designed mainly to help the managers become comfortable with the modelling software and with the basic structure of the system. Although is looks visually complex, this simple STELLA model helped the managers look as their assumptions more explicitly.

Improving the breakdown rate would allow the business to continue to grow and to remain profitable with that growth strategy.

Another critical lesson for the group was that policies across divisions within the company were all interdependent. Before their experience with the model, the managers viewed the company in a highly fragmented way. Even within the Equipment Servicing Division, the financial and quality camps saw the others as “obstacles” to be overcome. As a result of our intervention, the groups saw the need to look more systemically at the issues, and formed cross-division teams to continue the work.

A final realization for this group was that downsizing might be as much the disease as the cure. The group voted to postpone additional downsizing for at least a year.

Epilogue

I wish I could say that they lived happily ever after. The business line is still alive, which was in some doubt at the time, but they continue to have difficulties. I suspect that having cross-divisional teams was a very difficult structure to maintain, given their historical operations. I do feel, however, that our work helped them become more insightful and systemic in their approach.

Running through different simulations began to give them an understanding of the delays inherent in their service business — which was half the battle. For the first time, the group was able to test their assumptions about the way their business worked — and when you are caught in a “Fixes that Fail” or other problem-solving dynamic, exploring assumptions is always a good place to start.

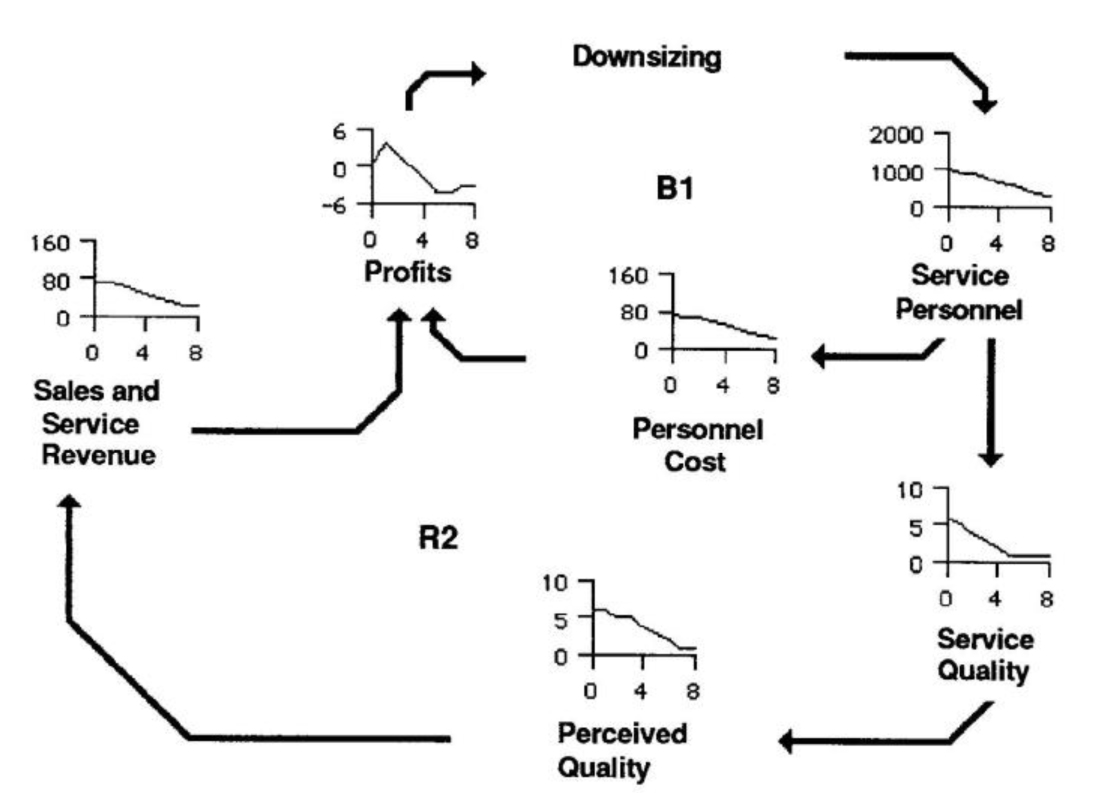

Unintended Consequences

The simulation revealed the “better before worse” effects of downsizing on profitability, which may have resulted from the delayed effects of reduced service quality caused by the downsizing. (Note: This diagram is from a HyperCard interface that was developed for the model at a later date, in conjunction with Brian Kreutzer of Gould-Kreutzer Associates.)

Critical Business Parameters

The real leverage for the Equipment Servicing Division was to restructure their business by Editorial support for this article was provided fundamentally changing some of the parameters that were within its control, such as Average by Kellie T. Wardman. Salary, Time Spent per Service, Failures per Product and Revenue per Product (in bold italic).