Several years ago, I was approached by a California-based software firm focused on electronic design automation. Their software enabled hardware engineers to efficiently design electronic devices for computers. Among their key clients were global companies such as IBM, HP, Intel, and Motorola.

The software firm wanted help with problems related to the roll out and sales of their new products. Specifically, they wanted assistance in developing a clear intervention strategy and action plan for addressing their Time to Volume (TTV) performance, a measure that tracked the sales performance of their new software products. The TTV was defined as the time in months that products took to reach their targeted or forecasted sales volumes. If the actual TTV was longer than expected, it meant that products were not taking off and that clients weren’t adopting the next generation of software in a timely way.

TEAM TIP

Unfortunately, the company’s data for the previous 24–36 months of new product launches indicated not only that the TTV was much longer than planned, but that the products were not reaching the expected sales volume at all (see “Forecasted vs. Actual Time to Volume”). This very serious business condition had prompted the request for my help. The assignment focused on the question, “Why is the TTV of our new products failing to meet expectations?”

The executive VP who contacted me was convinced that the TTV problem was systemic in nature and required a different approach than the company had used before. He also believed that the “field” (sales, marketing, and service) and the “factory”(software developers) needed to work together efficiently and leverage their resources to solve the issue. At this point, the factory was sure that the field did not support the new products and never seriously tried to sell them to key customers. The field pointed the blame at the factory, claiming that they were out of touch with real customer needs and unresponsive to the field’s suggestions and feedback. The two entities engaged ina lot of blame and finger pointing. The VP’s goal was for senior managers to recognize, own, and resolve the TTV issue on their own and break the dependency on top management to fix the problem for them.

Three Phases

After taking on the assignment, I collected data and gathered stories through phone interviews. The intervention developed naturally into three phases. The first phase was the design and facilitation of a two-day offsite for all the top senior managers (60 people) around the TTV issue. The purpose of this gathering was to get collective agreement about what the issue was, not to try to solve it. It was also intended to introduce many of the tools of systems thinking to the senior managers and have them apply them to the issue in cross organizational teams.

The second phase was an intensive mapping process around the TTV issue, starting with the data generated at the offsite. A task force developed the system maps with only minimal assistance. My role was to teach and show them the process, and their job was to apply it with some coaching support from me. By “learning through doing,” the team developed internal capacity in systems thinking for the company through work on a compelling business issue and generated deeper ownership of the analysis.

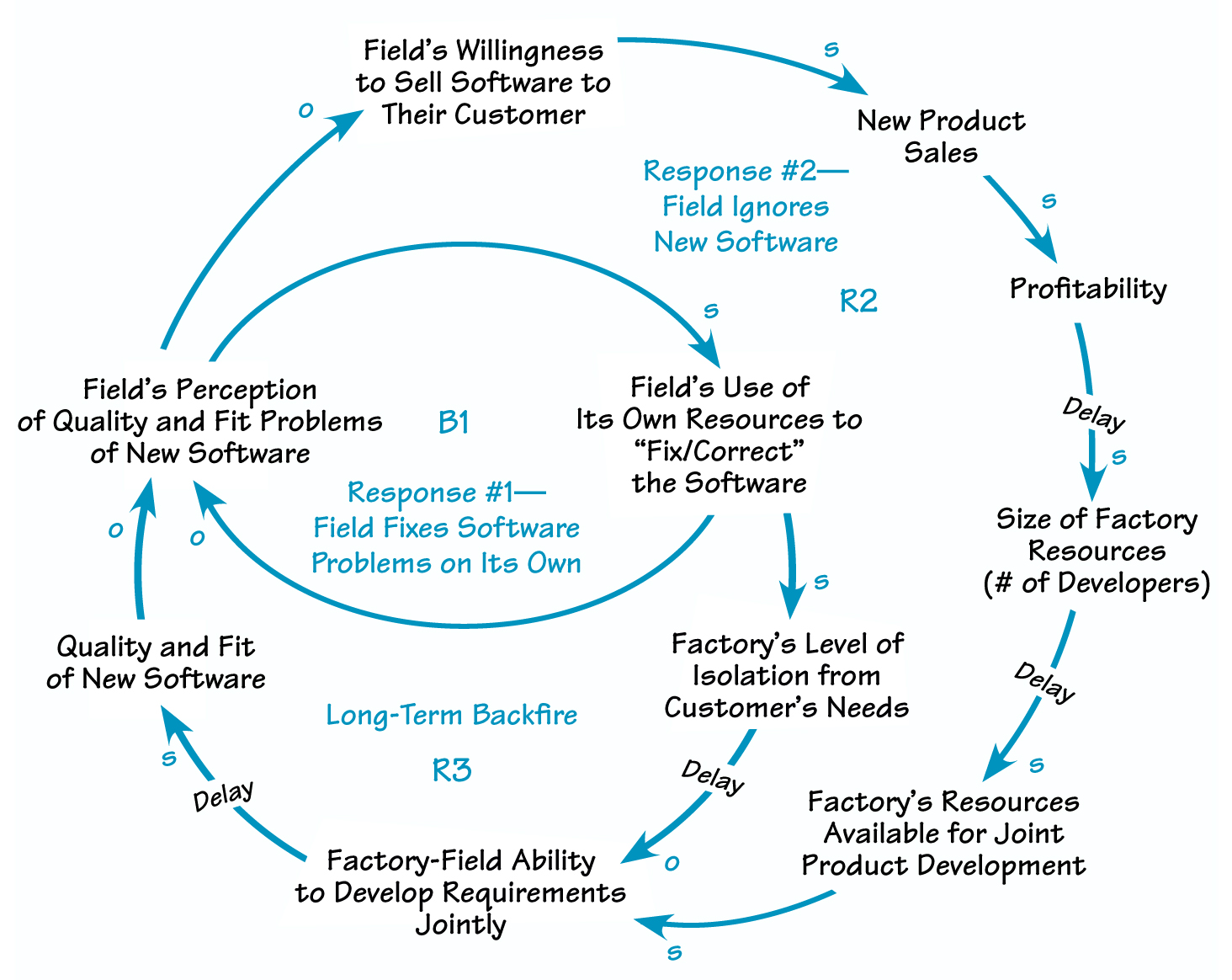

One of the stories that the team developed is shown in “The Field Isolates the Factory.” This example of the “Fixes That Fail” archetype captures how the field responds to new products that they perceive as being flawed or a poor fit for their customer’s needs. The field’s actions isolate the factory (software designers)from the customers (market place)and, over the longer term, erode the factory’s ability to develop high quality and appropriate products for the field’s customers.

The last phase focused on developing and implementing systemic recommendations. Here, the task force stepped back from the mapping process to see what higher-leverage fixes to the TTV problem emerged. They identified key mental models and experimented with applying interventions to the diagrams they had generated. Members then prepared an executive presentation for the VP and fellow senior managers detailing their analysis and making the systemic case for different interventions.

THE FIELD ISOLATES THE FACTORY

“Admiring” the Problem

The process described above had a variety of impacts. For one thing, the process and tools of systems thinking both broadened and deepened understanding and ownership of the TTV problem across the field and factory. After two days together, the senior managers recognized that the problem involved all parts of the organization and that they needed to take a system wide, longterm approach. They could no longer point fingers at other parts of the organization.

One simple indicator of this shift in attitude was a poll I took at the beginning of the offsite and then repeated at the very end. Just as we began, I asked for a show of hands from the participants as to whether they thought they knew what the TTV problem was and how to fix it. About 85 percent of the hands went up, indicating that participants were pretty sure they knew what the cause and solution were. I then repeated the same questions at the end of the session, and the results were startling. No one raised their hand! From my perspective, after two days, the group truly came to “admire” the TTV problem. They acknowledged that there was no simple fix and were now open to looking much deeper to address the root causes. This was progress.

Another impact was the fact that senior mangers initiated their own process to work on the issue. They not the VP or the consultant—chartered a task force that included thought leaders from the field and the factory and launched the second phase of the process.

Additionally, “undiscussables” and “sacred cows” were finally surfaced publicly. Apparently, this kind of openness had never really happened before, at least in a larger group setting. The use of loops and archetypes made it safe for “difficult” stories and, “truths” to be shared without the typical finger-pointing or defensiveness that often happens around high stake issues. By way of example, the task force labeled or headlined each of their archetype stories (there were about 10 different stories that emerged from the analysis) with descriptive and insightful themes such as “The Field Isolates the Factory,”, “Heroism Undermines the Product Development Process,” “Divided We Fail,” “Planning by Panic,” and “Poor Product Fit Gets Worse.” The identification of the mental models from both the field and the factory that lay behind many of the actions and reactions captured in the loops was also extremely telling.

Based on this application of systems thinking tools, the organization shifted from “Who is responsible for this?” to “How are we all contributing to the problem?” The task force was able to identify a number of tactical and strategic recommendations, including an early warning and measurement system, which were readily supported by all the senior managers. The archetypes and mental models revealed a story that touched all parts of the company and made the compelling case for why it was everyone’s problem to solve.

Michael Goodman is principal of Innovation Associates Organizational Learning. He is an internationally recognized speaker, author, and practitioner in the fields of systems thinking, organizational learning, and leadership. Michael is a regular presenter at the annual Systems Thinking in Action® Conference and was a major contributor and editor of the systems thinking chapters in The Fifth Discipline Fieldbook. He helped develop the systems archetypes and has been published many times in The Systems Thinker. Michael’s consulting work, workshops, and capacity-building work have taken him all over the planet.