Our brains are pattern-making systems — they organize our perceptions of the world into patterns that enable us to function effectively. For example, when we eat, our brain follows a particular set of patterns that guides the use of our fork and the amount of pressure we apply to our knife, without having to think about and make decisions at each choice point. The simple fact that we can recognize the fork as a fork is a result of our pattern-making ability.

Edward de Bono, author of Lateral Thinking and I Am Right You Are Wrong, likens the patterns in our brains to well-worn grooves. He explains that if we inside pour a teaspoon of hot ink over a plate of JELL-0, the ink will dissolve parts of the gelatin as it flows over the surface and form grooves. Any additional ink is likely to flow into the already-formed grooves and further deepen them. Our brain organizes and groups related pieces of information in the same fashion.

The grooves are not just passive receptacles of new information, however; they are active “channelers” of our perceptions into already-formed patterns. When customer orders fall, for example, that information gets channeled through the “beef up marketing” or “cut prices” groove in our brain. This process serves us well as long as those grooves are relevant for making sense of the situation. It is ineffective, however, in responding to new changes in the environment, since the new information is channeled into the same old pattern. Over time, it can actually lead to patterned blindness — the inability to see anything but the established pictures we already have in our brains.

TQM and the Learning Organization

If our current grooves affect both what we see and how we interpret what we see, how can we ever break out of this circular trap? How can we overcome our patterned blindness?

One way out of old patterns is through theory. Creating a new conceptualization of an issue can open our eyes to different possibilities by allowing us to let go of what we think we already know. Becoming a learning organizaton, for example, means being committed to continually asking the question, “How do we know what we know?”

This requires the ability to see old things in new ways and also to “see” things conceptually that we have not yet seen visually. That is the important role of theory — to see in the mind’s eye what we have yet to experience or know. In that respect, theories are like windows into the unknown.

In the 1980s, TQM offered a new theory that helped cut fresh grooves into our thinking about people, systems, and management. But TQM is only one step in the journey toward becoming a learning organization. Systems thinking is another important discipline that brings additional theories, tools, and methods for building the capabilities of a learning organization. Together, TQM and systems thinking can help organizations see beyond their patterned blindness and work toward building a better understanding of their own organizational capabilities and structures. By becoming theory-builders, managers can help their organizations become creators of their own future.

Patterned Blindness

At the turn of this century, craft producers of automobiles “knew” that costs were constant regardless of volume. Because of the meticulous, labor-intensive process used, the cost of producing the 100th car was more or less the same as for the first one. But mass production, with its economies of scale, dramatically altered the cost-volume relationship. By the 1920s, mass production had virtually wiped out the craft producers.

Likewise, in the early 1980s, the Japanese shattered the cost/quality trade-off myth with high-quality, low-cost products. In the process, they invented a new way of doing business — lean production — that was every bit as radical as the shift from craft to mass production (see “Lean Production: From the Machine Age to the Systems Age,” August 1991). Those who could not adapt shared the fate of the craft producers: in the U.S. and elsewhere, whole industries were nearly decimated (steel, machine tools, motorcycles, video cameras, televisions, memory chips, etc.).

These are not examples of small competitive ups and downs, in which poor decisions led to problems in one or two companies. In these cases, the fundamental basis of competition had shifted, requiring a radical change in perspective that some companies were unable to make. It is not that the new competitors kept the technology from the others; people simply could not recognize the implications of that shift because of the grooves in their brains — patterned blindness.

A clear example of this patterned blindness appears in the book The Machine that Changed the World. A General Motors plant manager (from one of the worst plants in the study) went to Japan to visit one of Toyota’s best assembly plants. After he came back, he was asked what he thought of the plant. He claimed that he was not shown the whole plant; Toyota must have been hiding something. Why? Because the plant was much smaller than his, even though their production capacity was the same. The Toyota plant had significantly less square footage, less working inventory, and no rework area.

He saw the layout of the plant, and yet he could not see beyond the patterned grooves in his brain that told him what a “real” assembly plant looks like. The fact that Toyota did not need a rework area because the cars were driven straight off the assembly line to the shipping dock lay outside this plant manager’s groove.

Problem Solving: Helping or Tampering?

Patterned blindness often operates in a disguised form — problem solving. How many times have we heard, ‘The problem is we need the latest flexible manufacturing system…The problem is we need more patient beds…The problem is we need more sales staff…The problem is…?” These are solution statements masquerading as problem statements, and they are a product of our individual mental grooves.

The Marble Experiment: A Theory in Action

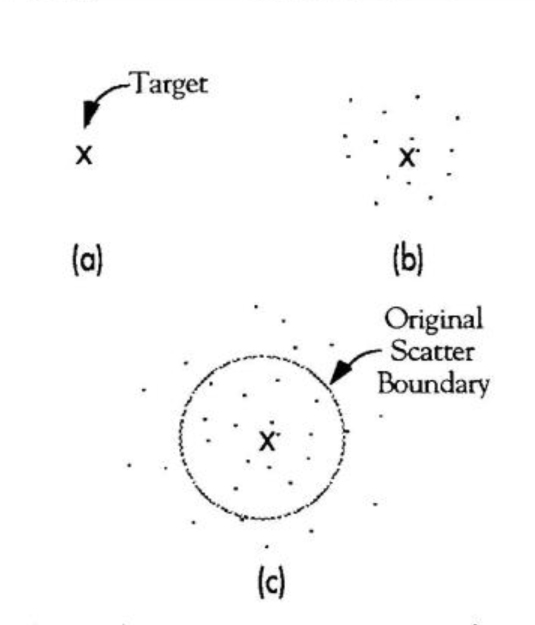

Now make one change in the process. Instead of aiming for the target spot, try instead to compensate for the error of the previous drop. If, for example, your first marble drop was two millimeters to the north of the target, aim two millimeters south of the mark. It seems like a reasonable change in strategy. After all, if your gun sights were off, you could consistently compensate for it by adjusting your aim accordingly. Does this strategy actually help in the marble experiment? No. The pattern of dots gets bigger; the dispersion increases rather than decreases (c).

This result runs counter to our intuition that making adjustments should help us reach our goals, not make it worse. In fact, statistical theory suggests that if a system is within its limits, well-intentioned adjustments will actually take us further from our goal.

When our thinking is entrenched in these types of solution responses, we do not bother looking for alternatives because the answer seems so clear. These grooves, in practice, embody our theory of the way the world works. We may think theory is an esoteric term that has no place in practical matters but, in fact, theory affects everything we see, think, and do. As Dr. Edwards Deming once said, “No theory, no learning.” Without theory, we cannot learn, because we cannot make sense out of the jumble of infinite stimuli that we are exposed to at every instant.

One of the ways Deming demonstrated his point about theory was by conducting illustrative experiments. Using a marble, a piece of paper, and a pen, for example, he showed how corrective actions intended to improve performance actually make things worse (see “The Marble Experiment: A Theory in Action”). Intuition says, “If there are deviations, take corrective actions.” Statistical theory counters, “If a system is in control, do nothing.” But in the absence of a clear theory, it is extremely difficult for most people to stand there and do nothing when it seems as if errors are being made.

Statistical Process Control

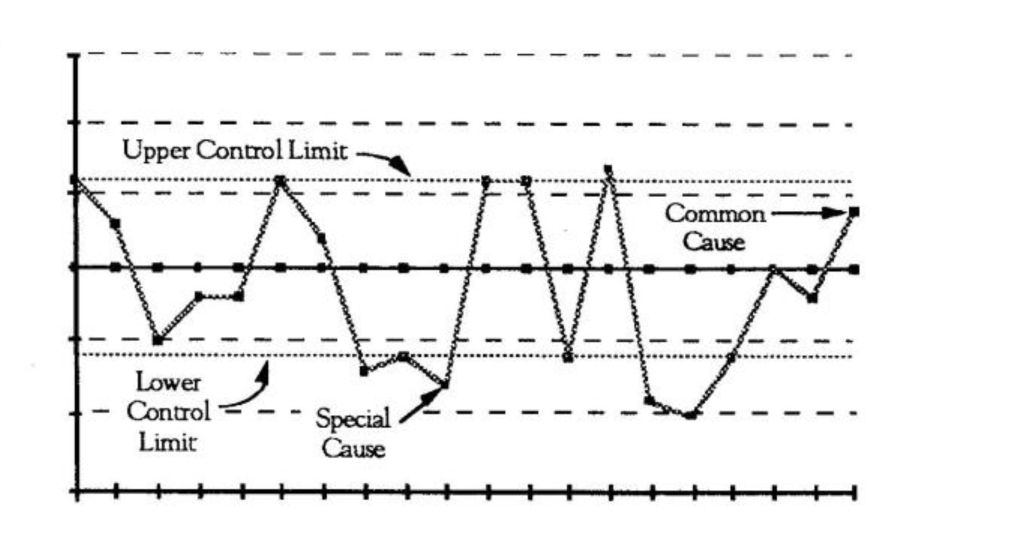

In the field of Total Quality, statistical theory was translated into a methodology called statistical process control (SPC). SPC provides a set of steps for distinguishing between special and common causes of variation. For example, control charts plotted with upper and lower limits around a target help to identify the boundaries of a system’s capability (see “Special vs. Common Causes”). Anything inside of those boundaries are classified as “common” causes for which no corrective action is necessary. Points outside of those limits are identified as “special” causes, meaning something has happened that is uncharacteristic of that system and needs to be investigated further. Special causes can be addressed by working within the existing system, but the common causes can only be addressed by changing the system itself.

Prior to the arrival of SPC, helpful “adjustments” like those in the marble experiment were actively being carried out in most manufacturing operations. If, for example, you wanted a rod whose length was 30mm ± .1mm and it came out larger or smaller, you naturally adjusted the calibration on the machine. In the absence of statistical theory with which to interpret the data, people would implement solutions (make adjustments) that actually increased the problem (greater deviations) and justified further corrective actions (more adjustments). That is, the solutions themselves guaranteed the need for more of the same solutions in the future.

Working with Multiple Theories

The application of SPC to manufacturing operations has resulted in great success because the theory is well-suited for controlling processes that are governed by physical laws and relationships. But statistics becomes less useful when we venture into the domain of social systems because many of the assumptions about predictability, repeatability, and linearity are not as appropriate. Therefore, as the use of TQM methods has become more widespread, they have been applied to a wider range of settings with decreasing levels of success.

Because social systems do not behave like mechanical and electrical systems, applying theories and tools better suited for the latter is not likely to enhance our understanding of the former. This does not mean that the theory behind TQM methods is wrong; it simply means that we have reached the limits of their usefulness.

All theories have limits that define the boundaries of their relevance. Newtonian physics, for example, was not proven “wrong” when Einstein developed his relativistic view of the world. Einstein’s theory of relativity simply defined the boundaries in which Newtonian physics worked and where it broke down. When you begin to approach the speed of light, Newtonian concepts of time and distance can no longer be treated as constants, but as relative concepts that are very much dependent on the reference frame from which you are making the measurements. For our day-to-day needs, however, Newton’s laws adequately approximate reality.

In some of his more recent writings, Deming acknowledged the limited role of statistics in the larger arena of organizational transformation. He identified three other theories that were important: systems theory, psychology, and theory of knowing. He believed that the set of four were essential for developing what he called “profound knowledge.” In his book The Fifth Discipline, Peter Senge presented five disciplines — shared vision, personal mastery, team learning, mental models, and systems thinking — that embody a range of theories about how to develop the capabilities of a learning organization.

Both Deming’s and Senge’s approaches draw on multiple theories, and both highlight the importance of understanding systems. In fact, systems thinking plays a particularly important role in developing learning organizations because the tools and methods of system dynamics enable you to not only be a user and interpreter of theory, but also an active theory builder. And theory building is essential to building learning organizations.

Feedback Loops a Theory-Building

System dynamics, pinning of systems thinking, allows us to articulate causal interconnections so that we can take high-leverage action instead of being paralyzed by complexity. System dynamics, which is grounded in feedback systems and control theory, provides a set of tools and methods for making sense of complex interconnections — similar to how TQM helps us understand variation through statistical theory. With respect to learning, TQM is particularly strong in operational learning — building greater understanding of how to do things — while systems thinking is relatively strong in conceptual learning — developing richer theories about why things work the way they do.

In the systems thinking toolkit, there are two types of feedback loops we can use to build our own causal theories of organizational behavior — reinforcing and balancing. A reinforcing loop represents a process where a change in one direction is continually amplified in the same direction (see “Anatomy of a Reinforcing Loop,” February 1994). In a balancing loop, a change in one direction produces a response that will try to take the system in the opposite direction. It is basically a control loop (see “Balancing Loop Basics,” p. 7).

Causal Loop Theory Building

With these two basic types of loops, we can construct rich theories about the causal interrelationships that drive our organizational behavior. Causal loop diagrams not only provide a language for representing dynamic structures, but they also provide a way for us to make explicit and share the individual views of the world that govern our actions. By surfacing our individual assumptions about our organizations, we can work toward building a coherent and consistent working theory about our organization and our environment.

Special vs. Common Causes

Special causes lie outside both the upper and lower control limits and are dealt with by working within the curers system. But because common causes lie within the control limits, addressing them requires a change in the system itself.

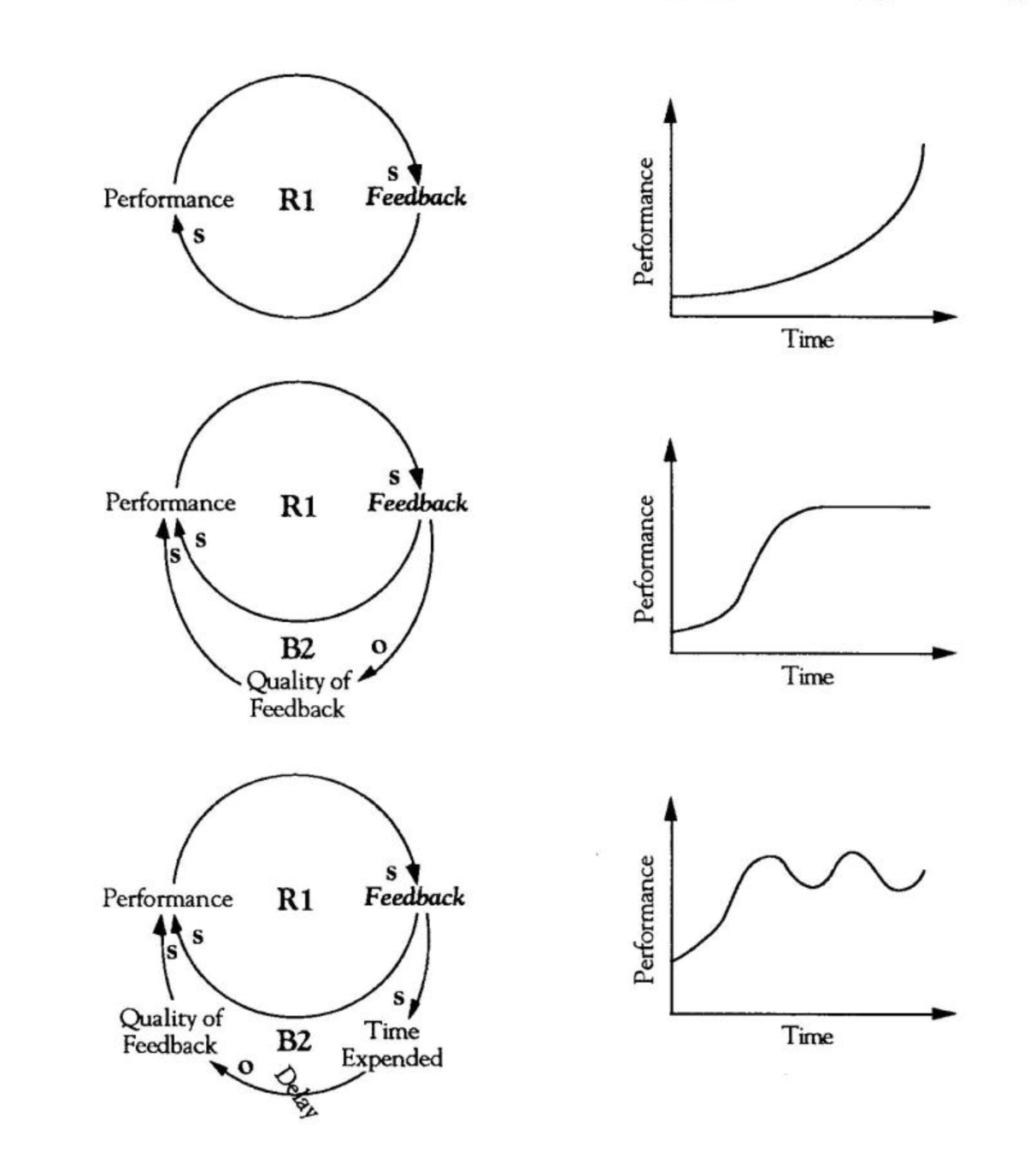

For example, one theory you may have is that increasing levels of feedback to employees will lead to increased performance over time, which leads to even more feedback (R1 in “Performance-Feedback Theory”). The pattern of behavior suggested by this loop is one of exponential growth. This is a testable theory. Data collection may reveal that performance rises initially, but after a while it plateaus. Someone else may suggest that performance can actually decrease if the quality of feedback is low, and that increasing feedback may actually lead to a decrease in the quality of the feedback (B2). A third person may add that it is not the increasing feedback that leads to lower quality of feedback, but the amount of time expended in giving feedback. As the time expended increases beyond a certain point (indicated by a delay), the quality of feedback suffers.

This example describes the beginnings of a theory about how feedback and performance are linked. Working through this as a team can reveal our collective understanding of what we think is going on in our organization. Causal loop diagrams and systems archetypes therefore provide us with a way to construct our theories; statistical tools can help us test the validity of the causal connections we have identified. In this way, both systems thinking and TQM are essential to the theory-building process.

Performance-Feedback Theory

Cutting New Grooves with Theory

Buckminster Fuller used to say that we start with the universe, and then recognize that any distinctions from then on are entirely arbitrary. In other words, the boundaries that we draw are not a product of nature but of our thoughts. Thus, theory plays a critical role in how we create the conceptual patterns through which we see our world and how susceptible we are to patterned blindness.

If we view the world through our theories (or patterns in our brains) then by becoming active theory builders we can greatly enhance the learning capacity of our organizations. Systems thinking and TQM provide a complementary set of theories and tools for developing an organization’s theory-building capabilities. Our ability to develop new theories will allow us to get out of existing grooves in thinking, to envision a whole different future, and then take the necessary steps toward creating that future. That is the exciting promise and potential of becoming a learning organization.