Since the mid-1990s, a tidal wave of firms have begun outsourcing all or part of their products and services. The two remaining U. S. automakers have recently spun off their multi-billion-dollar component businesses so they can focus on their core design and assembly operations. Many personal computer manufacturers, such as Hewlett-Packard, are farming out their notebook computer products to manufacturers in Taiwan. In the software industry, the rise of contract software designers in the “three I’s” — India, Ireland, and Israel — represents a prominent trend. Some firms have even gone so far as to outsource the very decision of whether or not to outsource.

THE SECRET’S OUT

In this way, the vertically integrated firms of yesteryear are transforming themselves into the virtually integrated supply chains of today. As such, many businesses are moving from producing all of their final products’ components and services internally to buying them from a network — or supply chain — of external suppliers. Why are so many companies taking this dramatic step? The benefits of this new business model include lower parts or service costs, lower up-front investment, and less financial risk if expected sales volumes do not materialize. But outsourcing has hidden drawbacks that may take several years to emerge. Ultimately, these “outsourcing traps” may actually increase a firm’s cost structure, reduce its products’ competitiveness, or in the worst case, lead to the emergence of new competitors.

How can businesses manage this major shift without falling into an outsourcing trap? Research shows that the design of a company’s supply chain is of decisive importance. In his book Clockspeed: Winning Industry Control in the Age of Temporary Advantage (Perseus Books, 1998), Massachusetts Institute of Technology professor Charles Fine argues that supply chain design may be a business’s most important competency, and that deciding which components to make and which to buy profoundly influences long-term corporate survival. While conducting research for Professor Fine, we discovered that the key to making wise sourcing decisions is to understand the short- and long-term trade-offs of different choices.

Although supply chains are now hot topics within Fortune 500 companies, smaller firms have long recognized their importance. For example, consider a mortgage company. As soon as a home-buyer applies for a mortgage, the mortgage company requests a customer credit report from a supplier such as Informative Research. The supplier compiles its reports from several credit databases maintained by credit repository companies such as Trans Union. At this point, the mortgage bank that will actually fund the loan (which is often separate from the mortgage company) must examine and provisionally approve the loan. In most American states, once the bank provisionally approves the loan, the mortgage company orders a property appraisal, a flood certification, and a title insurance policy, each of which is provided by a separate firm with its own supply chain. Finally, at closing, the mortgage company collects its commission and turns the loan over to the mortgage bank. Many mortgage banks in turn sell their mortgages to another investment institution.

Coordinating all of these firms to provide the end customer with a complete product is a complex process, but similar transactions occur throughout the business world. Designing a supply chain to operate as efficiently and profitably as possible is a difficult but potentially fruitful endeavor. For example, a normal mortgage company takes two to three weeks to go from application to closing. However, one mortgage company we work with has brought both the mortgage bank and appraisal functions in-house. By underwriting its own loans, conducting its own appraisals, and establishing close relationships with local builders, this company can “crash” a mortgage from application to closing in 48 hours if necessary, thus improving customer service. Mortgage companies that do not have these internal capabilities cannot equal this performance. This “simple” example illustrates the critical importance of supply chain design resulting from sourcing decisions.

Although outsourcing has been extensively examined in the academic literature, most of this work has focused on topics such as the economies of scale that it can offer. We are aware of few sources that examine outsourcing from a systems perspective, taking into account the intricate relationships, time delays, and feedback processes that relying on a vendor sets into motion. Systems thinking and system dynamics provide the perfect tools to examine the trade-offs. Companies that fail to apply this level of analysis to the decision-making process may seriously undermine their competitive position by falling into one of the outsourcing traps.

Common Outsourcing Traps

As part of our research, we developed a system dynamics simulation model that identified several circumstances in which an organization may experience short-term gains from outsourcing followed by devastating — and unexpected — long-term consequences. We call these “outsourcing traps.” Three of the more interesting traps are:

An organization may experience short-term gains followed by devastating longterm consequences. We call these “outsourcing traps.”

- A company loses its market dominance when its supplier acquires its proprietary technology and diffuses it to its competitors.

- A company relies too heavily on a single supplier, which weakens its ability to negotiate favorable purchase agreements.

- A company outsources a component or service to a vendor to reduce costs, only to encounter higher expenses or reduced functionality when putting the final product together.

We examine each of these dynamics in more detail below.

Boosting — or Creating — a Competitor

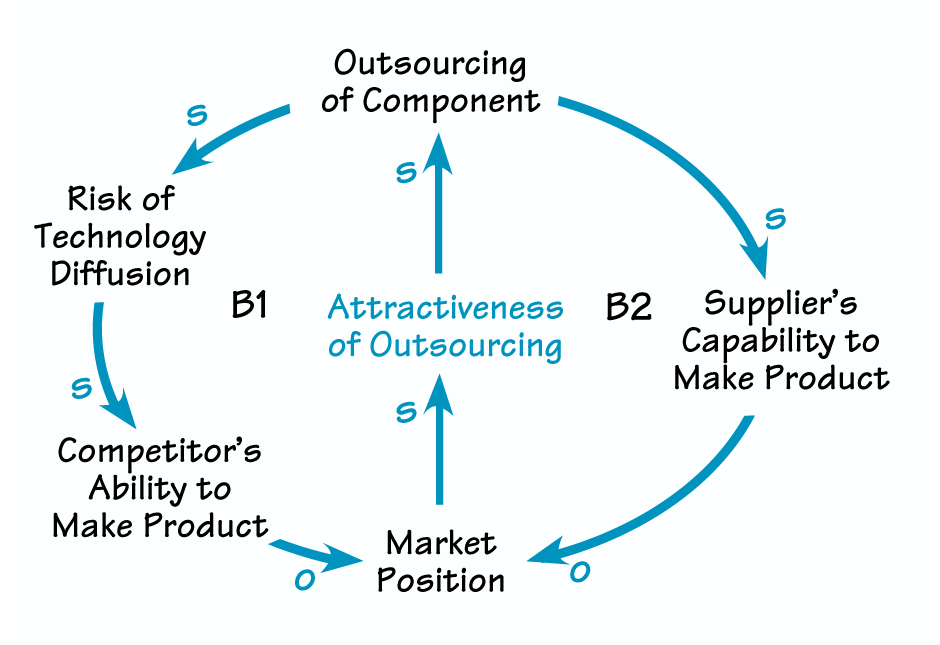

One possible consequence of outsourcing is that a competitor may gain access to critical technology through a common supplier. This can occur when the supplier offers the technology for purchase or when the supplier’s engineers bring the knowledge gained from working with the original firm to projects with other companies. If a competitor then uses the information to duplicate or improve on the original product, it may erode the first company’s market position (see B1 in “The Secret’s Out” on p. 1).

The classic example of this dynamic occurred when IBM was developing its new personal computers (PCs) in the early 1980s. The company made what turned out to be a crucial decision to outsource production of the PC’s microprocessor to Intel and development of its operating system to Microsoft. Little did IBM know that by doing so, it was opening the door for direct competitors such as Compaq and Dell to purchase the two components of the PC that are most difficult to duplicate. The result is that IBM today is only the third-largest maker in an industry that it created.

General Motors and Ford may have fallen into this trap when they decided to spin off their component divisions. The two new companies, Delphi and Visteon, are busily expanding their customer base beyond their parent corporations. As they do so, the risk of another automaker gaining access to once-proprietary technology grows. GM and Ford’s knowledge of the components may also become obsolete, leaving them helpless to make any innovations in component performance.

Auto companies may be most vulnerable in the area of automotive electronics, which has become the decisive factor in advancing car comfort, safety, and performance. Toyota is avoiding this trap by bringing some of its automotive electronics back inhouse after 45 years, even though its supplier, Denso, is the world leader in cost and quality. Toyota sees electronic components as critical to automobile performance and wants to keep at least some of its technology proprietary to gain a market advantage. It has made this move just as U. S. manufacturers are divesting themselves of this same capability.

“The Secret’s Out” also shows another twist on this situation. As the supplier grows more efficient at making the component and learns more about the component’s functionality, it may become sufficiently skilled at manufacturing the entire product to become a direct competitor (B2). U. S. consumer electronics firms fell into this trap in the 1960s and 1970s when they outsourced production of televisions and other electronics to Japanese suppliers. Ultimately, as domestic suppliers failed to develop their own capabilities, they fell further and further behind their own vendors. The suppliers eventually began to sell products under their own names — including Sony, Panasonic, and Mitsubishi — driving U. S. manufacturers such as Zenith and General Electric out of business. Today’s U. S. electronics and software companies may be repeating the same mistakes, as they increasingly outsource design activities to international suppliers.

Held Hostage by a Supplier

Another common but subtle outsourcing trap occurs when a supplier holds a firm hostage. If a company — or an industry — becomes too reliant on a particular vendor or set of vendors, power may shift to the supplier, allowing it to reap most of the profits. This dynamic is an extension of the IBM PC example above. Little did IBM know that the PC assembly industry would become primarily a commodity business, as the functionality that differentiated performance migrated from circuit boards to semiconductor chips and software.

As Professor Fine emphasizes — and as IBM presumably learned the hard way — the key is to “outsource capacity, not knowledge.” When IBM farmed out the bulk of the PC’s intellectual property to the software and semiconductor houses, it gave up a great deal of power in the supply chain. Intel and Microsoft could sell to any number of circuit-board manufacturers that could readily duplicate IBM’s design, but IBM could purchase Intel-compatible processors only from Intel and Windows-compatible operating systems only from Microsoft. This virtual monopoly enabled Intel and Microsoft to capture the bulk of the profits in the supply chain.

IBM tried to buck this trend by developing OS/2, its own operating system, in the late 1980s. It was arguably a better operating system than Windows. However, customers would not buy it because most software applications available at the time functioned only on Windows. Furthermore, because Windows had many more users than OS/2, Windows customers could more easily trade documents or software with other users than could OS/2 customers. In the end, the OS/2 system did not offer enough new features to convince users to switch. Because of the difficulties in competing with Microsoft and Intel, IBM and many other PC firms are instead trying to expand beyond the unprofitable PC business by moving into the maintenance and technical support of PCs, which offers more comfortable profit margins. Others are outsourcing as much of their production as possible to Asian contract manufacturers with lower personnel costs.

Another possible adverse consequence to outsourcing is that a company may lose the ability to intelligently purchase components — and suppliers may take advantage of this ignorance and price them at a premium. An executive for a top PC manufacturer recently stated that when the company first outsourced its notebook computer manufacturing, it could do so efficiently. However, after three years, the technology had changed sufficiently that internal people no longer knew enough about the product to determine whether a contract bid was competitive — especially because they suspected their vendors of engaging in price collusion and price gouging. The suppliers had the PC company in a difficult position, because they knew that the firm could no longer make the product themselves and that they had even lost the ability to determine the cost of the products they were buying.

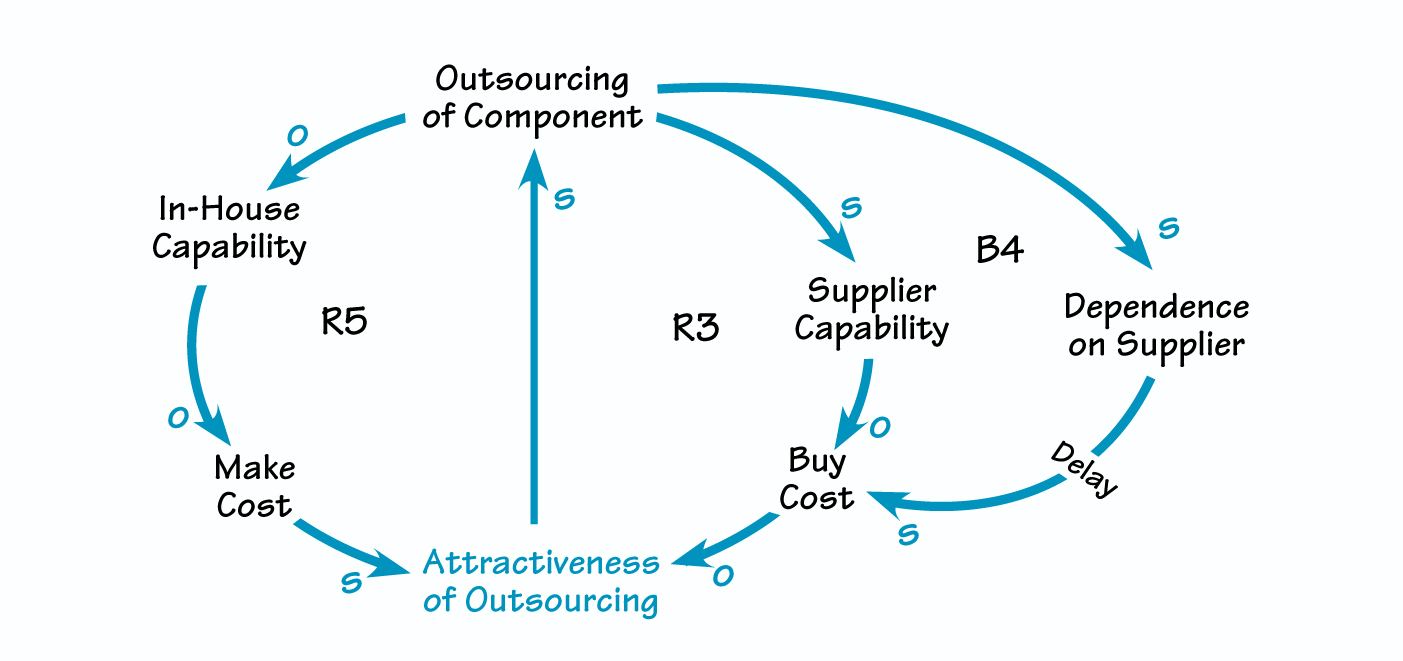

As shown in “Paying the Ransom,” outsourcing initially decreases the cost to purchase the product (R3). As the supplier gains leverage and the firm loses it ability to determine the component’s cost, the supplier may eventually boost the price above what it would have cost the original company to produce if it had not outsourced it in the first place (B4).

The danger of falling into this trap is especially acute for companies that outsource a component to one supplier for a long period of time. Lack of expertise within the original company about creating the component leads to increased in-house manufacturing costs, which makes outsourcing even more attractive (R5). This “Success to the Successful” dynamic can prove costly if the firm ever desires to make the part again. As time passes and the knowledge of how to make the component diminishes, it can become prohibitively expensive to reverse the outsourcing decision. If the firm determines in the future that this component is vital to the performance of the product, it may need to invest heavily to bring the knowledge back in-house. However, this penalty may be necessary to regain some bargaining leverage with suppliers.

PAYING THE RANSOM

Reassembling Humpty Dumpty?

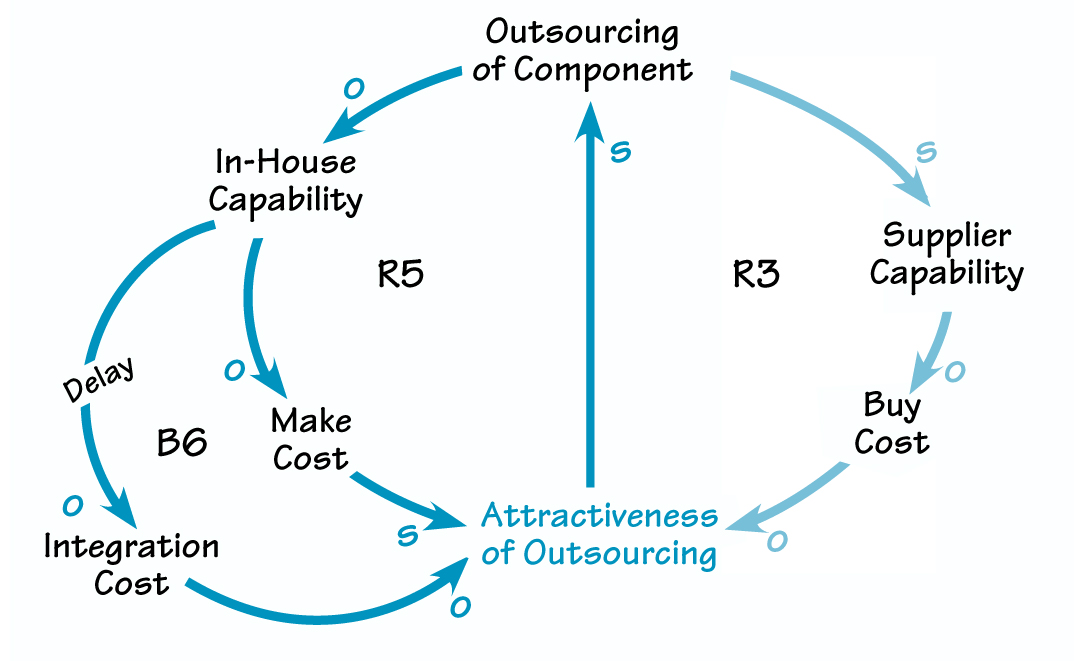

A firm also needs to know enough about its components to effectively integrate them into a single coherent product. As stated earlier, firms commonly choose to outsource because they can purchase a component from a supplier for much less than they can make it themselves. However, outsourcing may weaken more than just a firm’s ability to make and price a component; it may damage its ability to integrate multiple components into a final product.

Industry experts believe that one of the reasons Toyota decided to bring production of its electronic components back in-house was so that it could better integrate those components into a coherent whole. Forty years ago, automobile electronics were confined primarily to radio, lighting, and starter systems. Understanding electronics was not essential to automotive design. However, electrical systems control nearly every aspect of modern cars — from engine responsiveness to suspension behavior. Without understanding the intricacies of automotive electronics, it is difficult for manufacturers to design and produce cars that will meet customers’ expectations of automotive performance and comfort.

ALL THE KING’S MEN . . .

In another example, SAP, a German provider of enterprise-wide integrated software packages, experienced serious implementation problems with many of its North American clients. These software packages, often known as enterprise resource planning programs (ERPs), integrate all the information processing activities in a firm, from purchasing and manufacturing to order fulfillment and accounting. SAP ultimately traced its difficulties to its outsourcing of implementation to third-party consultants. Because SAP did not participate in the implementation process directly, the company did not gain knowledge to feed back into product improvements. Many of these problems have lessened since SAP began to join its alliance partners in actual implementation projects.

Manufacturing a component or performing a service can thus give a firm a decisive edge in knowing how to integrate it effectively into the final product (for more on this topic, see E. G. Anderson and G. G. Parker (2000), “Learning, Product Integration, and the Dynamics of the Make/Buy Decision,” University of Texas McCombs School of Management Working Paper, available from the author). Many of Microsoft’s detractors claim that the software giant uses its in-depth knowledge of the Windows operating system to give it an edge over its competitors in designing the features of its applications software. If this is true, then splitting Microsoft into an operating systems company and an applications software company may have a hidden cost to the consumer. The new applications company may become less familiar with Windows as the operating system changes over time and former Microsoft employees leave, leading it to design less effective products.

The third trap can lead to a possibly fatal balancing loop (see “All the King’s Men . . .”). As a company’s knowledge of its products’ components diminishes, integrating those components to provide a high-quality product or service can become prohibitively expensive (B6). Because the total product cost is the sum of the cost to make or buy components plus the cost to integrate them into the final product, any benefit received from cheaper components may be eliminated by increased integration costs.

Overcoming Outsourcing Traps

How does a firm overcome these outsourcing traps? One way is to avoid outsourcing altogether. This approach may be necessary for firms concerned about the leakage of proprietary knowledge through a supplier. If the company still wants to pursue outsourcing, it may need to have vendors sign binding nondisclosure agreements. However, even the best of these will only slow, not stop, the diffusion of knowledge. Companies cannot prevent suppliers from transferring personnel to projects for different clients. And, even if transfers could be stopped, as long as the supplier is selling to more than one customer, some information leakage will necessarily occur.

On the other hand, complete insourcing may not be the right solution. Companies that make components in-house may avoid the supplier hostage and systems-integration traps, but they must assume all the costs of producing the component or service. So, are there ways to obtain both the low risks and low integration costs of insourcing and the low component costs of outsourcing? We have found that there are (see, “Avoiding Outsourcing Traps” on p. 5). In many instances, by making just a small percentage of the components (or one of a number of similar components) in-house, a firm can maintain adequate knowledge to control many outsourcing risks and integration penalties while still reducing the average cost to make or buy those components. Toyota has pursued this strategy in its relationship with Denso. The automaker knows that it cannot produce electronics control systems more cheaply than its supplier, so it lets Denso produce most of the components. However, by designing and manufacturing others, Toyota can gain enough knowledge to utilize the full potential of its electronics control systems when designing new automobiles. This approach also helps prevent Denso from holding the company hostage.

Businesses can pursue a similar strategy when outsourcing services. Franchisers that also maintain company-owned stores are classic examples of partial outsourcing. For example, in 1988, Dunkin’ Donuts operated only 2% of its 1500 locations itself. However, it specifically used its company-operated sites to pilot all new distribution and marketing programs before asking the franchisees to adopt them.

The success of the partial outsourcing strategy depends on a number of variables, including economies of scale, the pace of technological change, and the modularity of components. But most important are the fixed costs associated with the component or service. If both the firm and its suppliers incur high fixed costs, then pursuing this partial outsourcing strategy may not be feasible. For example, silicon wafer fabs, which make semiconductor chips, cost several billion dollars to build and are unsuitable for low-volume production. Because of such huge capital requirements, partial outsourcing is unlikely to be cost-effective in this industry. On the other hand, in the software design industry, the majority of fixed costs—such as providing workers with high-end computers and Internet access—are based on the number of programmers employed. Hence, maintaining a small fraction of programming activities in-house is unlikely to be prohibitively expensive.

There are other possible solutions to the outsourcing dilemma as well. For example, a firm can lower its integration costs by hiring and training people with certain specific systems-integration skills, such as systems engineering. If employees carefully design a product so that its component interfaces are well defined and well understood, then the organization can avoid many thorny integration problems. For example, products that are designed to use “snap-in” components are usually much easier to assemble into a final product than those designed with parts that must be screwed into place. HewlettPackard has pursued this approach in tandem with increased outsourcing over the past five years.

Avoiding the IBM PC’s Fate

AVOIDING OUTSOURCING TRAPS

- Take the long view. Most outsourcing traps only reveal themselves in financial results after several years. By then, it may be too late to correct a mistake.

- Do not outsource your “core capabilities.” If a technology or service underpins your product’s competitive advantage, then you probably should not outsource it.

- Consider partial outsourcing of other critical capabilities. This approach may allow you to keep sufficient knowledge of your products’ component parts and services to keep integration costs low and prevent you from becoming too dependent on a supplier.

- If insourcing or partial outsourcing of a critical capability does not make financial sense, then consider using two or more suppliers. This strategy will keep the suppliers’ pricing competitive. However, it will also increase the opportunity for technology diffusion.

- Develop strategic alliances with suppliers. Give them economic incentives to keep costs low and to prevent technology diffusion.

In this article, we have looked at just a few of the difficulties that can result from a decision to outsource. The outsourcing traps highlight how a seemingly simple decision to have a vendor produce a component or service can have devastating effects on a company’s future well-being. Using system dynamics, we can look beyond the short-term benefits achieved by outsourcing and analyze the long-term consequences, including what effects these decisions may have on future economic and market positions. We can be almost certain that IBM’s management did not envision the future that it created when it chose to farm out its microprocessor to Intel and its operating system to Microsoft. Perhaps IBM’s fate in the personal computing market and the structure of the entire industry would have been different if the company had used the tools that system dynamics and systems thinking offer to anticipate the potential pitfalls— and promise—that supply chain design can offer.

Edward G. Anderson Jr., Ph. D., (Edward. Anderson@bus.utexas.edu) is an assistant professor of management at the University of Texas McCombs School of Business. His research focuses on employing systems thinking and system dynamics in outsourcing and other knowledge management issues. Mary Ann Anderson (CABS@texas.net) is a principal consultant with the Computer Aided Business Strategies Group in Austin, Texas. The firm provides strategic solutions to businesses utilizing system dynamics.

NEXT STEPS

- Develop a firm understanding of what makes your product or service more desirable than your competitors’—you may not want to outsource these capabilities.

- Identify the loops that dominate your business or industry. Such things as high integration costs, few capable suppliers, or reliance on proprietary technology offer valuable insight into whether a component or service is a good candidate for outsourcing.

- Use causal loop diagrams and computer simulations. Because of the complexity of the outsourcing decision and the serious consequences that it can produce, a system dynamics model may be useful to evaluate your outsourcing strategy under different scenarios.