The first three systems thinking skills help you establish an extensive (breadth) and intensive (depth) boundary for your mental or computer-based model. The next three systems thinking skills — Operational, Closed-Loop, and Quantitative Thinking — help you specify the relationships that reside within the boundaries you have established. This article focuses on Operational Thinking.

Defining the Skill

AN OPERATIONAL REPRESENTATION OF HOW LEARNING OCCURS

Although it is one of the most powerful thinking skills, Operational Thinking also appears to be one of the most difficult to master. The difficulty arises because the alternative thinking paradigm — Factors Thinking — is so deeply ingrained in most individuals. People using Factors Thinking ask “What factors influence . . . ?” or “What critical success factors drive . . . ?” In contrast, those exercising Operational Thinking look at the world in terms of how things really work. The difference here is between thinking correlationally and thinking causally. Consider the following illustrations.

One of the most popular books in recent times is Steven Covey’s, The Seven Habits of Highly Effective People. Covey lists seven “habits” that he claims characterize how highly effective people operate. He treats each habit as a separate and independent behavior to be learned. However, if you examine the habits from an “operational” perspective, you will discover that, far from being a “list” of independent behaviors, they reflect an interdependent web of relationships that govern how people should allocate their time in order to develop and sustain effectiveness.

The seemingly simple question, “How do you learn?” provides a second illustration of the distinction between the two kinds of thinking. People inevitably hear this question as “What influences your learning?” They usually respond with a list of factors that bear upon the rate at which they learn. Typical lists include motivation, teacher quality, IQ, parental involvement, quality of teaching materials, and so on. But these inventories do not describe how anyone learns anything!

The figure “An Operational Representation of How Learning Occurs” seeks to portray the process by which people actually learn. As shown, the activity basis for learning is an ongoing stream of life experiences. These experiences include such things as reading, doing, listening, conversing, and reflecting. People “take away” a certain amount of knowledge from each experience. The product of experiences and knowledge per experience defines the rate at which a person learns.

The Benefits

Thinking operationally has two principal benefits. First, it supports more effective communication. Second, it enables you to identify leverage points for improving performance.

Words are notoriously imprecise. This imprecision in turn limits our effectiveness in communicating what we really mean. Because it encourages “describing it like it is,” Operational Thinking imposes a substantially higher degree of precision in the use of words and thereby reduces the likelihood of misinterpretation.

To illustrate how thinking operationally can help in identifying leverage points, let’s return to the cows. After the dawning of my operational awareness, I realized that although the “variable to be forecasted is a function of . . .” approach may work well for predicting the future (if the historical correlations persist), it does little to surface levers for creating the future. So, if you want to increase milk production, you need to examine how milk is actually produced. Doing so yields “number of cows” and “milk per cow per year.” As a first lever for increasing U. S. milk production, you could grow the number of cows by either stimulating cow births or importing cows from outside the U. S. If you went either route, you would have to endure the associated delays (gestation in one case and logistical details in the other).

As a second lever to increase milk production, you could slow the rate at which cows exit the milk-producing stock — that is, increase the average length of time that cows remain productive. The third lever, looking at milk per cow per year, also raises operational issues, such as farmers’ ability to acquire automated milking technology and the speed with which they can assimilate new animal husbandry practices.

This example illustrates the shift in perspective that operational thinking brings about. Viewing milk production as “driven by . . .” external factors such as GNP is tantamount to assuming that it’s something that “happens to you.” Seeing milk as the product of cows causes you to focus on the actual levers that you can exercise to bring about change. Operational Thinking puts you in control of the leverage points for improving performance.

Honing the Skill

The first step in honing your Operational Thinking skills is to become more aware of when you are not thinking operationally. When you find yourself or your organization making a list of “critical factors” or “drivers” to explain a particular event or trend, complete that process. Then call a time out and ask, “What really causes this phenomenon? How does it actually work?” You’ll be surprised at how often the answer is as obvious as “cows” or “I learn through experience.”

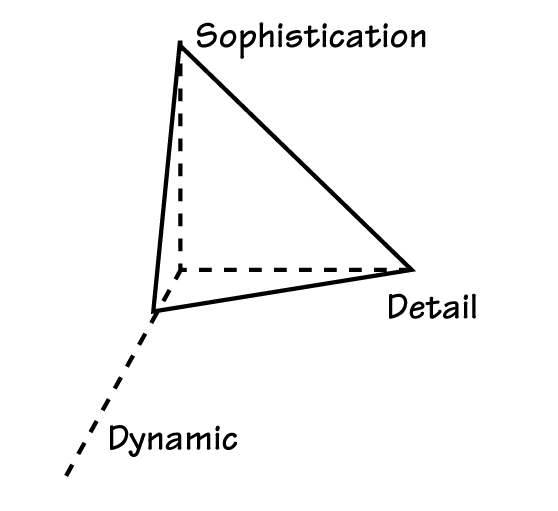

In thinking operationally about how something works, look for two categories of “production functions.” The first is stock-generated (like the stock of cows that generates milk production). The second is flow-generated (like the stream of experiences that generates learning). Think hard about which kind of production function best characterizes the activity or process you are examining. Doing so will force you to think in operational terms about what’s really going on in the activity under examination.

THE PROBLEM WITH BENCHMARKING

An Example

One of today’s hottest management approaches, benchmarking, provides a conspicuous example of correlation-based Factors Thinking. In benchmarking, organizations measure a variety of their operating ratios against “best-in-class” ratios to determine where they stand and what they need to improve. The problem with this approach is that operating ratios are not operational descriptions of how a business works but rather statistical calculations that correlate with performance.

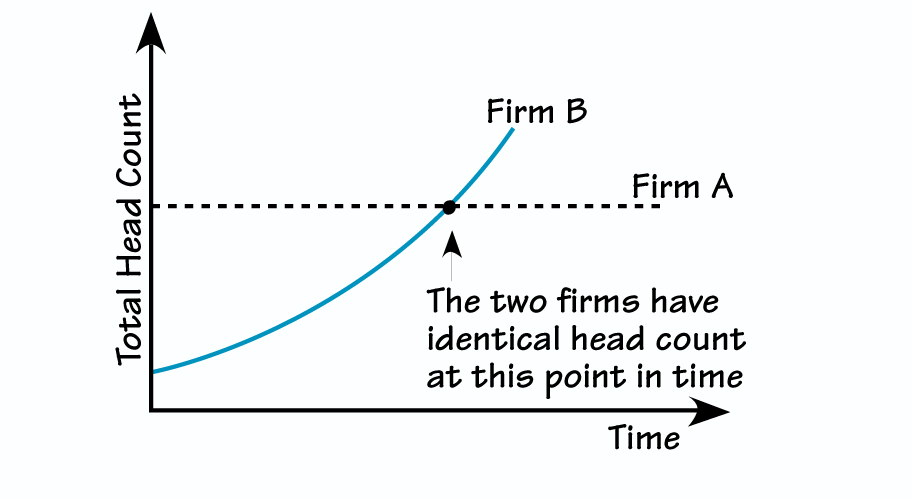

For example, a senior VP of a well-known technology company was puzzled by the fact that his organization’s human resources department didn’t “fit the model” — meaning that the ratio of HR professionals to total head count was significantly higher than “best in class.” Even more puzzling, HR consistently complained that they were terribly overworked!

Constructing a simple, operational model of demand for HR services shed significant light on the mystery. The model clearly showed that demand for HR services — for any given level of staffing — could be vastly different depending on the rate at which the number of employees was changing. As the figure “The Problem with Benchmarking” illustrates, a firm experiencing rapid growth in head count (such as this VP’s company) should expect far greater demands for HR services than an identically sized firm with stable levels of staffing. In this light, benchmarking an organization against a single, best-in-class standard can be very misleading.

Summary

Although the benefits of Operational Thinking are clear, implementing the skill poses a serious challenge for most adults. The reason for this difficulty is that correlationally based Factors Thinking is deeply ingrained in most of us. But honing your Operational Thinking skills will pay big dividends in terms of your ability to communicate effectively and identify levers for change.

Barry Richmond was the managing director and founder of High Performance Systems, Inc. He received a PhD in system dynamics from the MIT Sloan School of Management, an MS from Case Western Reserve, and an MBA from Columbia University.