The phones were ringing off the hook and the fax machine was humming 24 hours a day. The entire staff of the specialty goods company celebrated their most successful marketing campaign ever—more than double last year’s returns. But the celebrations were short-lived as the backlog of unfilled orders began to swell. The company’s standard 48-hour turn-around time grew to 72 hours, then ballooned to more than a week. The phones continued to ring — not with new orders, but with angry complaints about delays. The company was on the verge of a crisis.

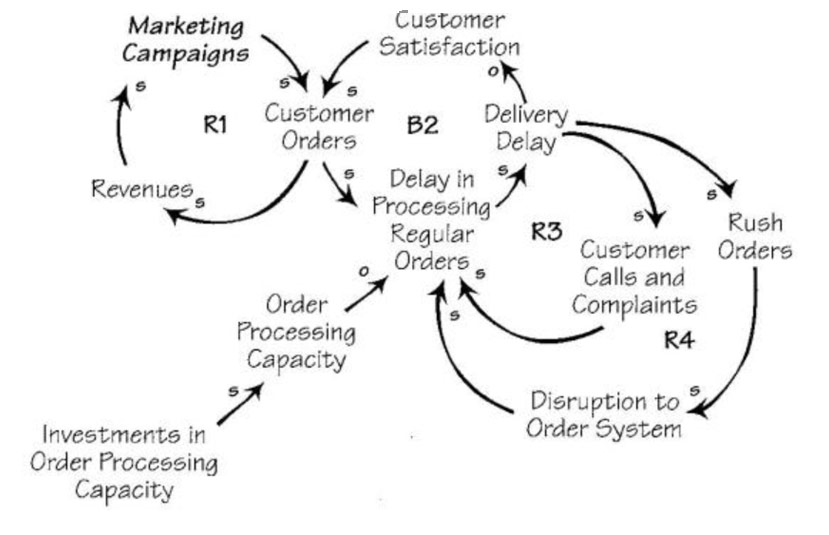

In order to get to the source of the problem, the management team convened an emergency meeting. They quickly recognized a potential “Limits to Success” situation: the marketing campaign had created a “virtuous” growth cycle, spurring sales and bringing in additional revenue, but the flood of new orders swamped the fulfillment department, leading to longer processing times and order delays (R1 in “Marketing Success and Capacity Limits”). Because they understood the dynamics of “Limits to Success,” they knew that if they didn’t solve the problem soon, it would resolve itself — customer orders would drop as news of the delivery delays spread (B2).

Marketing Success and Capacity Limits

When the group mapped out some possible consequences of the surge in orders, they discovered some interesting dynamics that they had not anticipated. When the orders started to take longer to process, customer calls and complaints increased dramatically. The people who processed orders were also the same ones who answered customer calls. Therefore, the more calls that came in, the further behind they would get in processing orders, which would lead to more calls (R3). This vicious cycle was chewing up more and more order processing capacity.

To make matters worse, the lengthening delivery delay had sparked another vicious cycle in the form of “rush” order requests. When customers found out how long the regular orders were taking, they took advantage of the company’s special “same day rush” service. Since the company’s system was not designed to handle so many rush orders, these requests created major disruptions in both order processing and shipping, which further increased the delivery delay (R4).

By the end of the meeting, it was clear to all involved that they needed to find a way to stop the spiraling dynamics that were leading to increasingly poor performance. But where was the best place to intervene in the system? What steps should they take?

From Insight to Intervention

Although the collective insight that comes out of a diagramming process can add much value to a team process, insight alone is not enough. In order for systems thinking efforts to impact organizational performance, those insights need to be translated into action. To be effective, an intervention must be self-sustaining and self-correcting, and it must address the underlying source of problems. Below is a four-step process for using systems thinking to design effective organizational interventions.

1. Map out the Intervention

Starting with a causal loop diagram or systems archetype representation of the problem, a first step is to look at where effective interventions can break vicious cycles, connect parts of the system, or reduce delays. By explicitly mapping those interventions, you can get a better sense of their impact on the system. Some possibilities:

Break a link.

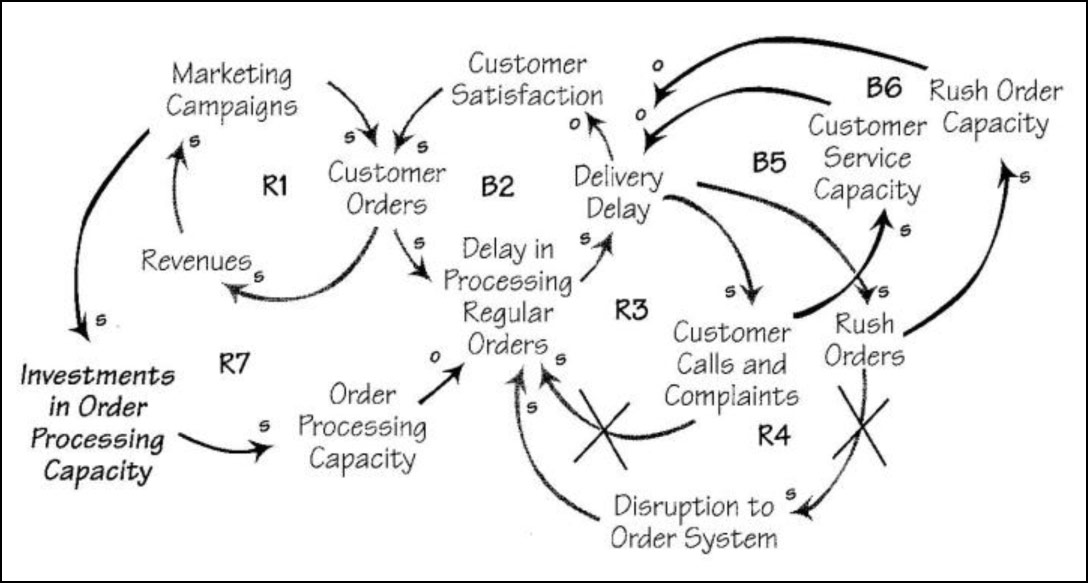

Look for ways to break the causal connection between two variables. For example, the fulfillment department could break the link between “Customer Calls and Complaint?’ and “Delay in Processing Regular Orders” by temporarily adding customer service representatives whose sole responsibility is to handle the calls (see “Possible Interventions”). This would decouple the vicious cycle of order processing and call answering and free the order fulfillment personnel to handle more orders (loops B5 and B6).

Add a link. You may find that there are parts of the system that should be communicating with each other but are actually not connected. Finding such information gaps and connecting them can help the system be more responsive to changing circumstances. For example, the management team recognized that they needed a way to balance demand for their product with their capacity to fill the orders before they fell behind. They realized that the signal from the delivery delay was arriving too late for them to successfully intervene, and that they needed to initiate capacity additions well before the marketing launch. Thus, for future efforts they should connect “Marketing Campaigns” with “Investments in Order Processing Capacity,” which would help sustain the marketing success rather than negate it (R7).

Shorten a delay. Identify the delays in the system, and map out a process for shortening them. Delays can be in the form of material or information flows, capacity expansions, or even changes in perceptions. They all add to the sluggishness of the system and can escalate minor problems into huge headaches. Addressing the delays in fulfillment capacity additions earlier in the process (as suggested above) would be a critical point of improvement.

Possible Interventions

Suggested Interventions for Each Archetype

If you are unsure of where to start in mopping interventions, you might see if your issues resemble any one of the generic systems archetypes. Each of the archetype structures contains one or more suggestions for specific interventions that may provide a starting point. For example:

Drifting Goals: Once you have made the goal explicit in your diagram, look for ways to anchor that goal to an external standard (which breaks the link between pressure to lower the goal and the goal itself).

Escalation: Drive the reinforcing engines in reverse by initiating a unilateral action that leads to de-escalation (such as shifting the focus to a different measure that is not win-lose).

Fixes That Fail: Find ways to break the link between the “fix” and the unintended consequences, or between the unintended consequences and the original problem symptom (which often means looking for a more fundamental solution, rather than a “quick fix”).

Growth and Underinvestment: Actively shorten the delays in the system — especially the perceptual delay in recognizing the need to invest in additional capacity.

Limits to Success: Identify and remove the constraint that is limiting growth, or intentionally slow growth by curtailing growth activities. Also, identify and address any unintended side effects of growth.

Shifting the Burden: Create a two-pronged attack of continuing to apply the symptomatic fix in the short term while you implement a fundamental solution.

Success to the Successful: The leverage here lies in “blowing apart” the two loops — breaking the connection between the two reinforcing processes so that the resources devoted to one group, project, or individual are not dependent on the performance of another group.

Tragedy of the Commons: Once you have identified the commons, determine what governing body is responsible for managing the commons and look for ways to add links that balance the net gain for each individual with the net loss of the common resource.

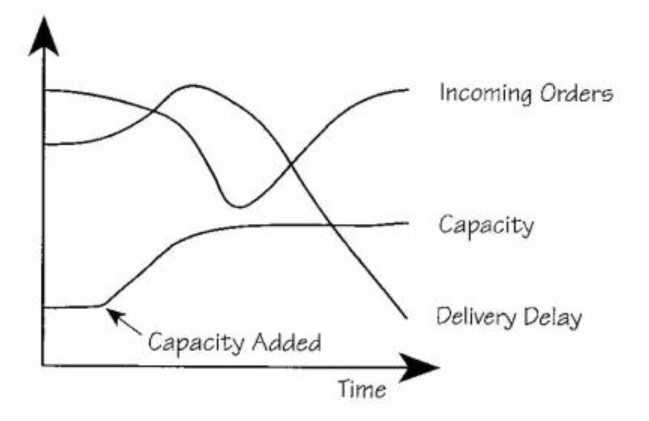

2. Draw out the Expected Behavior

Once you have mapped out some possible interventions, the next step is to try to evaluate the impact those actions might have on the system. You first want to identify the key variables that would be affected and then ask, “If we changed the system successfully, what new patterns of behavior would we expect to see?” By drawing out the expected behavior of key factors over time, you create a reference point against which you can check the actual outcome.

Expected Behavior

By drawing out the expected behavior of key factors over time. You create a reference point against which you can check the actual outcome.

In the case of the order fulfillment department, some key statistics that would be affected by a change were the time required to process orders, the number of orders, and the delivery delay. The managers expected the delivery delay to increase steadily in the short term while they invested in additional capacity and worked on making it fully productive. Once the new capacity came on line, however, they expected the delivery delay to decrease (see “Expected Behavior”). Orders were likely to continue to drop off even as delivery times shortened, but would eventually rebound over time as word got out about the improved delivery times.

The knowledge that delivery delays would continue to increase and that orders would continue to drop for a short while provided helpful indicators that the company needed to give the intervention enough time to make an impact on the system. Mapping out the expected behavior ahead of time gave everyone involved a common picture of what the interventions were going to produce, both in the immediate moment as well as in the long term. This foresight prevented unnecessary over-corrective actions from being taken when delivery performance did not improve right away.

3. Do Controlled Experiments

Before committing to any large-scale actions, it is important to run small, relatively self-contained experiments whenever possible and to use them as learning opportunities. Such experiments can provide a low-risk way to test interventions and see if they reveal any trade-offs between short-term and long-term results or if they produce any unintended side-effects. If the situation does not allow for direct, controlled experiments — either because the system is too complex and/or the time delays are too long — it may make sense to test the interventions by developing a computer simulation model that represents the key features of the situation (see “From Causal Loop Diagrams to Computer Models,” Part I and Part II, June/July 1994 and August 1994).

For example, the model building process helped the manufacturing company managers become clearer about the interactions between their marketing and order fulfillment departments. By running various scenarios of marketing campaigns mapped with different schedules of capacity additions, the group developed greater confidence in managing the balancing act between demand and capacity.

4. Get All Stakeholders Involved

A critical requirement for the successful implementation of most intervention efforts is getting the full support and commitment of critical stakeholders. This poses a dilemma for many managers: although it may be desirable to engage all stakeholders in the process of designing an appropriate solution, it is not always feasible to do so. And yet, it can be difficult for those people who are not directly involved in the design process to be fully supportive of the proposed solution. This is where a management flight simulator can be useful. An interactive simulator can engage those stakeholders in a thinking process similar to that experienced by the original design team. By testing their assumptions in the simulator, they can come to their own appreciation of the issues involved. (see “Management Flight Simulators—Flight Training for Managers,” Part I and Part II, November 1992 and December 1992/January 1993)

Long-Term Commitment

Keep in mind that there is no one right answer to any complex situation. The best interventions are likely to be a combination of carefully planned actions that are refined over time based on feedback from the system. Using causal loop diagrams to map out your current situation and your intended interventions can help you develop more robust strategies and address your problems more systemically. But it is rarely a one-shot deal — you need to continually review the performance of the over-all system, so you can learn to intervene before problems occur.

Colleen Lannon is co-founder of Pegasus Communications and the managing editor of The Systems Thinker™.